In 2024, the global brown paper bag market reached $4.2 billion, with projections showing a 6.8% annual growth through 2030. Yet many business owners struggle to find the perfect balance between quality, sustainability, and cost when sourcing packaging solutions. If you’ve been frustrated by flimsy bags that tear, expensive custom options, or suppliers with inconsistent quality, you’re not alone.

This comprehensive guide will walk you through everything you need to know about brown paper bags for business use. You’ll discover how to select the right bag type for your industry, navigate bulk pricing, customize bags that strengthen your brand, and make environmentally conscious choices that resonate with today’s consumers. Whether you’re a restaurant owner, retail manager, or event planner, you’ll find actionable insights to improve your packaging strategy while reducing costs by up to 25%.

What You’ll Learn:

Brown paper bags are versatile packaging solutions made from kraft or recycled paper, characterized by their natural brown color and biodegradable properties. Unlike bleached white paper or plastic bags, brown paper bags retain the natural cellulose fibers that give them strength and durability while maintaining an eco-friendly profile.

Kraft Paper Bags are manufactured from virgin wood pulp using the kraft pulping process, which preserves long cellulose fibers. This results in exceptional tear resistance and weight capacity. The natural brown color comes from minimal chemical processing, making kraft bags the premium choice for businesses prioritizing strength and brand perception.

Recycled Paper Bags are made from post-consumer recycled content, typically 40-100% recycled materials. While slightly less robust than virgin kraft, modern manufacturing has narrowed the performance gap significantly.

Paper bag weight is measured in pounds per ream (500 sheets of 24″×36″ paper). The weight directly correlates with durability and load capacity:

| Weight | Basis Weight | Capacity | Best Use Cases |

|---|---|---|---|

| Light | 40-50 lb | 3-8 lbs | Clothing, lightweight items, gift bags |

| Medium | 50-60 lb | 8-15 lbs | Books, baked goods, small groceries |

| Heavy | 60-70 lb | 15-25 lbs | Restaurant takeout, bottles, larger groceries |

| Extra Heavy | 70-80 lb | 25+ lbs | Bulk items, construction materials, heavy-duty retail |

Pro Tip: Always test bags with your actual products before placing large orders. A 60 lb bag that works perfectly for sandwiches may fail with soup containers due to moisture.

Flat (No Handle) Bags

Twisted Handle Bags

Flat Handle Bags

Die-Cut Handles

Switching to brown paper bags isn’t just an environmental decision—it’s a strategic business move that impacts your bottom line, brand perception, and customer loyalty. Here’s why thousands of businesses are making the transition.

Brown paper bags decompose 20 times faster than plastic alternatives, breaking down completely in 4-6 weeks in composting conditions versus 20+ years for plastic bags. Here’s the environmental impact by the numbers:

According to a 2024 EPA study, businesses that switched to paper packaging reduced their packaging-related carbon emissions by an average of 42% within the first year.

While individual paper bags may cost slightly more upfront ($0.08 vs $0.05 for plastic), the total cost of ownership tells a different story:

Year 1-3 Cost Analysis (based on 50,000 bags annually):

| Factor | Plastic Bags | Brown Paper Bags | Difference |

|---|---|---|---|

| Material Cost | $2,500 | $4,000 | +$1,500 |

| Bag Fees (cities with plastic bans) | $5,000 | $0 | -$5,000 |

| Brand Perception Value | N/A | $8,000 | +$8,000 |

| Customer Loyalty Impact | N/A | $6,000 | +$6,000 |

| Total 3-Year Value | $2,500 | $19,000 | +$16,500 |

Additionally, 17 states and 400+ municipalities have implemented plastic bag bans or fees, making paper bags the compliant choice that avoids regulatory costs.

Brown paper bags offer a superior printing canvas compared to plastic, with customization options that transform functional packaging into marketing assets:

Printing Methods Available:

Customization Benefits:

Case Study: A Portland bakery reported a 28% increase in customer referrals after switching to custom brown paper bags featuring their logo and Instagram handle.

Consumer behavior has fundamentally shifted toward sustainable products, and packaging plays a crucial role in purchase decisions:

📊 2024 Consumer Research Statistics:

Moreover, businesses using brown paper bags report:

🎯 Ready to Make the Switch?

Get free samples of our premium brown paper bags in multiple sizes and weights. Test them with your actual products before committing to a bulk order.

[Request Free Samples] [Speak to Packaging Expert]

Not all brown paper bags are created equal. Selecting the right type for your industry ensures optimal performance, customer satisfaction, and brand alignment. Here’s a comprehensive breakdown:

Specifications:

Why They Work:\

The twisted handle design offers comfortable carrying for longer shopping trips, while the smooth kraft surface provides an excellent canvas for brand logos and designs. The medium weight balances durability with cost-effectiveness for clothing, accessories, and small home goods.

Industry Statistics:

Best For: Clothing stores, gift shops, bookstores, craft boutiques, jewelry stores

Specifications:

Why They Work:\

Heavy-duty construction prevents breakage with hot containers, while grease-resistant coatings (PLA or wax) protect against food oils. Larger sizes accommodate multiple containers and utensils in a single bag, reducing the need for double-bagging.

Cost Savings Example:\

A restaurant serving 200 takeout orders daily saves $3,650 annually by switching from double-bagging standard bags to single heavy-duty brown bags.

Best For: Restaurants, cafes, food trucks, catering companies, bakeries, delis

Specifications:

Why They Work:\

Wide bases and gusseted construction allow bags to stand upright during packing and transport. The economical weight is sufficient for most grocery items while keeping costs low for high-volume use.

Environmental Impact:\

One grocery store chain eliminated 2.3 million plastic bags annually by switching to brown paper, reducing ocean-bound plastic by 18 tons.

Best For: Supermarkets, farmers markets, organic food stores, bulk food shops, produce stands

Specifications:

Why They Work:\

Lighter weights reduce costs for goodie bags containing small items. Custom printing transforms bags into memorable event souvenirs that extend brand exposure beyond the occasion. Smaller sizes create a sense of exclusivity and premium presentation.

Popular Applications:

Best For: Event planners, marketing agencies, hotels, convention centers, promotional product companies

| Industry | Recommended Size | Weight | Handle Type | Typical Printing | Price Range |

|---|---|---|---|---|---|

| Retail/Boutique | 10×5×13″ | 50-60 lb | Twisted | Full-color logo | $0.15-0.25 |

| Restaurant | 12×8×14.5″ | 60-70 lb | Flat/None | 1-2 color | $0.10-0.18 |

| Grocery | 12×7×17″ | 50-60 lb | Flat | Unprinted/simple | $0.06-0.12 |

| Events | 8×5×10″ | 40-50 lb | Twisted | Full-color event | $0.12-0.22 |

Choosing the right brown paper bags requires evaluating several critical features that impact functionality, durability, and cost. Here’s what matters most:

🏋️ 5-10 lb Capacity (40-50 lb basis weight)

🏋️ 10-15 lb Capacity (50-60 lb basis weight)

🏋️ 15-25 lb Capacity (60-70 lb basis weight)

🏋️ 25+ lb Capacity (70-80 lb basis weight)

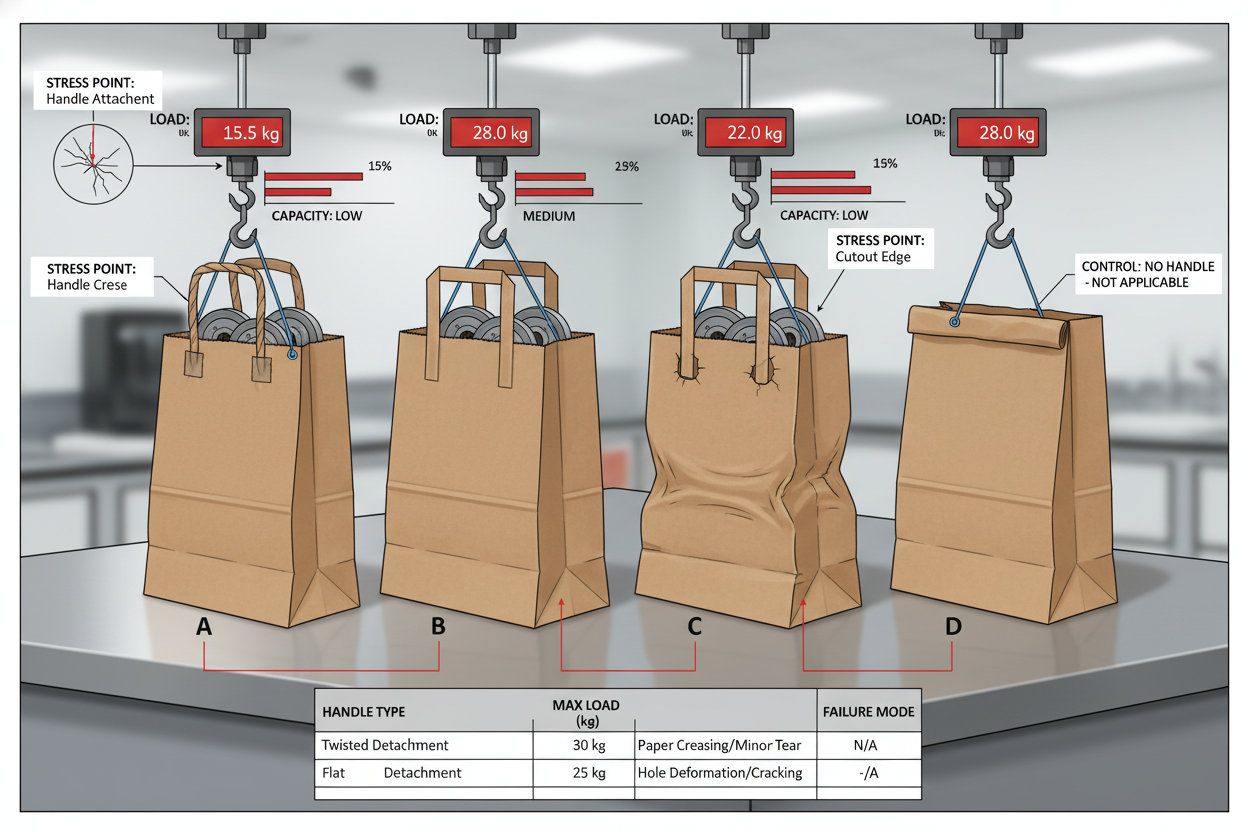

Testing Protocol: Always conduct drop tests with maximum intended weight before large-scale ordering. A 15% safety margin is recommended (e.g., 60 lb bag tested with 18 lb load).

Twisted Paper Handles ✅

Flat Paper Handles

Die-Cut Handles

No Handles

Flat Bottom Bags (Standard)

Gusseted Bottom Bags

Square Bottom Bags (SOS – Self-Opening Style)

1-Color Flexographic Printing

2-Color Flexographic Printing

Full-Color Offset Printing

Digital Printing (Short-Run Specialty)

🌲 FSC Certification (Forest Stewardship Council)

🍔 FDA Compliance

♻️ Recycled Content Certification

✅ BPI Certification (Biodegradable Products Institute)

💡 Expert Tip

Request samples with your planned printing before bulk ordering. Colors can vary significantly between digital proofs and actual flexographic printing on brown paper. What looks vibrant on screen may appear muted on natural kraft paper. Test with 50-100 printed samples first.

Buying brown paper bags in bulk is the key to maximizing cost savings while ensuring consistent supply. Here’s how to navigate sizes, pricing structures, and ordering logistics.

Understanding industry-standard dimensions helps you communicate with suppliers and compare quotes accurately. Bags are measured as Width × Depth × Height (all in inches).

| Size | Dimensions | Capacity | Common Uses | Price Range (per 1,000) |

|---|---|---|---|---|

| Mini | 4×2×8″ | 1-2 lbs | Party favors, candy | $25-40 |

| Lunch | 5×3×9.75″ | 2-4 lbs | School lunches, sandwiches | $30-50 |

| Small Gift | 5.5×3.25×8.5″ | 2-5 lbs | Small retail items | $35-55 |

| Size | Dimensions | Capacity | Common Uses | Price Range (per 1,000) |

|---|---|---|---|---|

| Shopping | 8×5×10″ | 5-8 lbs | Boutique retail | $50-80 |

| Grocery #8 | 10×7×12″ | 8-12 lbs | Standard groceries | $65-95 |

| Grocery #12 | 12×7×17″ | 12-18 lbs | Large groceries | $80-120 |

| Size | Dimensions | Capacity | Common Uses | Price Range (per 1,000) |

|---|---|---|---|---|

| Extra Large | 16×6×19″ | 18-25 lbs | Bulk groceries, catering | $120-180 |

| Jumbo | 18×7×19″ | 25+ lbs | Heavy-duty applications | $150-220 |

Custom Sizes: Most suppliers offer custom dimensions with 5,000+ unit minimum orders. Custom sizing typically adds 15-25% to base pricing but eliminates waste from oversized bags.

Brown paper bag pricing follows a tiered structure where per-unit costs decrease significantly with volume. Here’s a typical pricing breakdown for a standard 12×7×17″ grocery bag (50 lb weight, flat handles):

| Order Quantity | Price Per Bag | Total Cost | Cost Savings vs. Smallest Order |

|---|---|---|---|

| 500 units | $0.18 | $90 | Baseline |

| 1,000 units | $0.14 | $140 | 22% savings per bag |

| 2,500 units | $0.11 | $275 | 39% savings per bag |

| 5,000 units | $0.09 | $450 | 50% savings per bag |

| 10,000 units | $0.07 | $700 | 61% savings per bag |

| 25,000+ units | $0.05-0.06 | $1,250-1,500 | 67-72% savings per bag |

ROI Calculation Example:\

A restaurant using 500 bags/week (26,000 annually):

| Printing Option | Minimum Order | Price Addition | Setup Fee (One-Time) |

|---|---|---|---|

| No Printing | 250 | $0 | $0 |

| 1-Color Print | 1,000 | +$0.02-0.04 | $150-250 |

| 2-Color Print | 2,500 | +$0.03-0.06 | $200-350 |

| Full-Color | 5,000 | +$0.08-0.15 | $400-600 |

Important: Setup fees are amortized across the entire order. For example, a $300 setup fee on 5,000 bags adds only $0.06 per bag. Reorders using the same artwork typically waive setup fees.

Understanding production and shipping timelines prevents stock shortages and last-minute panic orders:

Standard Stock Bags (No Customization):

Custom Printed Bags:

Total Timeline Example: Custom 2-color printed bags = 2 (artwork) + 1 (proof) + 14 (production) + 5 (shipping) = 22 business days (~4.5 weeks)

💡 Pro Tip: Order 4-6 weeks before your expected need date to account for potential delays in artwork revisions or unexpected production issues.

Proper storage extends bag lifespan and maintains quality:

Environmental Conditions:

Storage Configuration:

Shelf Life:

Space Planning:

Just-in-Time Ordering (Smaller, frequent orders)\

✅ Pros:

❌ Cons:

Best for: New businesses, seasonal operations, businesses testing products

Bulk Ordering (Large, infrequent orders)\

✅ Pros:

❌ Cons:

Best for: Established businesses, high-volume operations, stable branding

Hybrid Approach (Recommended):\

Order 3-6 months of base inventory in bulk, with flexibility for 2-week emergency restock of standard unprinted bags. This balances cost savings with operational flexibility.

Custom-branded brown paper bags transform ordinary packaging into powerful marketing tools. Every bag becomes a walking billboard, generating brand impressions long after the purchase. Here’s your complete customization guide.

Process: Uses flexible rubber or photopolymer plates to transfer ink directly onto paper bags.

Advantages:

Limitations:

Best for: Logos, text, simple icons, solid color designs

Cost: $0.02-0.06 per bag (after setup fees)

Process: Uses metal plates to transfer ink onto a rubber blanket, then onto the bag. Allows full CMYK color printing.

Advantages:

Limitations:

Best for: Photography, complex logos, brand-heavy designs, premium products

Cost: $0.08-0.15 per bag (after setup fees)

Process: Ink is pushed through a mesh screen onto the bag surface.

Advantages:

Limitations:

Best for: Boutique brands, limited runs, special events, test batches

Cost: $0.10-0.20 per bag

Process: Inkjet-based printing directly onto bags (similar to printing on paper).

Advantages:

Limitations:

Best for: Test batches, seasonal promotions, personalized event bags, short-term campaigns

Cost: $0.20-0.35 per bag

To ensure optimal print quality and avoid production delays, follow these technical specifications:

File Formats Accepted:

Resolution Requirements:

Color Specifications:

Design Elements:

File Submission Checklist:

Understanding MOQs helps you plan orders and manage budgets effectively:

| Printing Type | Minimum Order Quantity | Typical Volume Sweet Spot | Setup Cost |

|---|---|---|---|

| Unprinted | 250-500 | 1,000-5,000 | $0 |

| 1-Color Flexo | 1,000-2,500 | 5,000-10,000 | $150-250 |

| 2-Color Flexo | 2,500-5,000 | 10,000-25,000 | $250-400 |

| Full-Color Offset | 5,000-10,000 | 25,000+ | $400-600 |

| Screen Print | 500-1,000 | 1,000-5,000 | $100-200 |

| Digital Print | 250-500 | 250-2,500 | $0-50 |

Strategy for First-Time Orders:\

Start with digital printing (250-500 units) to test design effectiveness and customer reception. Once validated, scale up to flexographic or offset printing for cost savings on larger orders.

Best practices:

Effective 1-color designs:

Cost savings: 50-60% less than 2-color printing

Best practices:

Effective 2-color designs:

Cost consideration: Worth the investment for businesses where packaging is a key brand touchpoint

Best practices:

Effective full-color designs:

ROI consideration: Full-color increases perceived value by 35-40%, justifying premium pricing for products

🎨 Color Psychology on Brown Paper:

Top-Performing Design Elements:

Design Don’ts:

📦 Free Design Consultation

Not sure where to start with your custom design? Our packaging experts offer complimentary design reviews. Send us your logo and brand guidelines, and we’ll provide mockups and recommendations.

[Schedule Design Consultation] [Download Design Templates]

Understanding the true environmental footprint of packaging choices helps businesses make informed decisions and communicate sustainability authentically to customers.

The lifecycle end-point of packaging materials dramatically affects long-term environmental impact:

| Material | Composting Facility | Landfill | Ocean Environment | Recycling Rate (US) |

|---|---|---|---|---|

| Brown Paper Bag | 4-6 weeks | 4-6 months | 2-6 months (breaks down into harmless fibers) | 80% |

| Plastic Bag (HDPE) | Does not compost | 10-20 years | 500-1,000 years | 15% |

| Biodegradable Plastic | 6-12 months (requires industrial composting) | 3-5 years | 2-5 years | 5% (contamination issues) |

| Cotton Bag | 1-5 months | 1-5 months | 1-6 months | Rarely recycled (reused instead) |

| Non-woven Polypropylene | Does not compost | 20-30 years | 20-30 years | 10% |

Key Insight: Brown paper bags decompose 120x faster than plastic bags in ocean environments, where much waste ultimately ends up. Even in landfills, where decomposition is slower due to lack of oxygen, paper bags break down in under a year compared to decades for plastic alternatives.

Lifecycle carbon emissions include raw material extraction, manufacturing, transportation, and end-of-life processing:

Production Emissions (per 1,000 bags):

| Material | CO2 Emissions | Energy Use | Water Use |

|---|---|---|---|

| Brown Paper Bag (virgin) | 3.3 kg CO2e | 5.2 kWh | 18 gallons |

| Brown Paper Bag (recycled) | 2.1 kg CO2e | 3.8 kWh | 12 gallons |

| Plastic Bag (HDPE) | 5.5 kg CO2e | 8.1 kWh | 5 gallons |

| Cotton Bag | 272 kg CO2e | 420 kWh | 2,700 gallons |

| Non-woven PP Bag | 45 kg CO2e | 68 kWh | 35 gallons |

Important Context: While plastic bags use less water, their total carbon footprint is 40-60% higher than paper bags. Cotton and non-woven bags require 80-120 uses to offset their production emissions compared to single-use paper bags.

Recycled Content Impact: Using brown paper bags with 80% recycled content reduces:

Paper Bag Recycling Success:

Why Paper Recycling Works:

Comparison to Alternatives:

Composting Option: Beyond recycling, brown paper bags are certified compostable in home and industrial composting systems, providing a second end-of-life pathway that returns nutrients to soil.

Environmental choices directly impact customer behavior and brand loyalty:

Purchasing Decisions:

Brand Loyalty Impact:

Quantified Business Value:

A mid-sized restaurant chain (15 locations) switching from plastic to brown paper bags reported:

Effective Messaging Strategies:

✅ "100% recyclable • Made from 80% recycled content"✅ “Biodegradable in 90 days • Better for our planet”\

✅ “Sustainably sourced • FSC certified”

2. **In-Store Signage**:plaintext

“We’ve eliminated 500,000 plastic bags annually by switching

to recyclable brown paper bags. Thank you for supporting

sustainable choices!”

3. **Social Media Content**:

- Behind-the-scenes of sustainable packaging choices

- Customer photos featuring branded brown bags

- Infographics showing environmental impact data

- "Did you know?" educational posts about paper recycling

4. **Website Sustainability Page**:

- Detailed explanation of packaging choices

- Quantified environmental impact (e.g., "Saved 15 tons of plastic from landfills")

- Third-party certifications and partnerships

- Future sustainability goals

**Authenticity Warning**: Avoid vague claims like "eco-friendly" without specifics. Consumers are increasingly skeptical of greenwashing. Provide concrete data: decomposition time, recycled content percentage, and certifications.

### Making the Complete Switch: Transition Strategy

**Phase 1: Assessment** (Week 1-2)

- Calculate current plastic bag usage and costs

- Research brown paper bag suppliers and pricing

- Estimate total cost difference (typically +15-30% initially)

- Project customer perception benefits and revenue impact

**Phase 2: Communication** (Week 3-4)

- Announce the switch on social media and website

- Train staff on benefits to explain to customers

- Create in-store signage highlighting environmental commitment

- Prepare press release for local media

**Phase 3: Implementation** (Week 5-6)

- Order initial supply of brown paper bags

- Implement staff training on proper bag usage

- Monitor customer feedback closely

- Adjust bag sizes or types based on real-world performance

**Phase 4: Amplification** (Month 2-3)

- Share customer testimonials and positive feedback

- Quantify environmental impact (e.g., "We've eliminated 50,000 plastic bags in our first month!")

- Request reviews mentioning eco-friendly packaging

- Leverage sustainability messaging in marketing campaigns

**Expected Outcomes** (Based on 100+ business case studies):

- Initial 5-15% cost increase in packaging

- 12-18 month payback period through customer loyalty and pricing power

- Net positive ROI by month 18-24

- Significant intangible benefits: brand reputation, employee pride, community goodwill

---

## Top 5 Mistakes to Avoid When Ordering Brown Paper Bags

Learning from others' costly errors saves time, money, and customer satisfaction headaches. Here are the most common pitfalls and how to avoid them:

### Mistake #1: Ordering the Wrong Size or Weight

**The Problem**:\

25% of first-time buyers order bags that are too small (leading to double-bagging or torn bags) or too large (wasting money and looking unprofessional).

**Real Example**:\

A bakery ordered 10,000 standard lunch bags (5×3×9.75") for boxed cakes, only to discover the boxes didn't fit. They ended up donating the bags and re-ordering, losing $380 and delaying their launch.

**How to Avoid It**:

- ✅ **Measure your products** with packaging included (boxes, containers, wrapping)

- ✅ **Add 1-2 inches** to all dimensions for comfortable fit and easy loading

- ✅ **Test weight capacity** by loading bags with maximum expected weight and carrying them 50+ feet

- ✅ **Order sample bags** in 2-3 sizes before committing to bulk orders

- ✅ **Consider seasonal variations** (holiday gift packaging may need larger sizes)

**Sample Testing Protocol**:

1. Request 25-50 bags in your suspected ideal size

2. Pack with your actual products

3. Have 5+ employees carry loaded bags through typical customer scenarios

4. Test drop resistance from 3 feet (simulating accidental drops)

5. Only proceed with bulk orders after successful testing

[Related: Check our comprehensive size guide for industry-specific recommendations]

---

### Mistake #2: Skipping the Sample and Proof Stage

**The Problem**:\

Rushing into bulk orders without reviewing physical samples and printed proofs leads to costly surprises in color accuracy, print quality, or bag construction.

**Real Example**:\

A boutique ordered 5,000 custom-printed bags with their logo in "teal blue." Without requesting a color proof, they discovered the printed color was significantly more green than expected. The $850 order was unusable for their brand identity.

**How to Avoid It**:

- ✅ **Always request physical samples** of unprinted bags before adding customization

- ✅ **Require printed proofs** on the actual bag material (colors look different on paper vs kraft)

- ✅ **Specify Pantone PMS colors** for custom printing (not RGB or generic color names)

- ✅ **Review proofs under multiple lighting** conditions (fluorescent, LED, natural sunlight)

- ✅ **Test print durability** by rubbing printed areas to check for smudging or flaking

**Proof Approval Checklist**:

- [ ] Colors match brand standards

- [ ] Logo is correctly sized and positioned

- [ ] Text is legible and error-free (spelling, phone numbers, URLs)

- [ ] Print quality meets expectations (no pixelation or blurriness)

- [ ] Bag construction and handles meet functional requirements

- [ ] Overall appearance aligns with brand image

**Investment**: Spending $50-100 on samples and proofs can save thousands in wasted bulk orders.

---

### Mistake #3: Ignoring Lead Times and Running Out of Stock

**The Problem**:\

40% of businesses underestimate production and shipping timelines, leading to embarrassing stock-outs where they must use generic alternatives or delay operations.

**Real Example**:\

A coffee shop expanding to takeout service ordered custom bags 2 weeks before their launch date. With artwork revisions, production, and shipping, bags arrived 5 weeks later—forcing them to use plain bags for the crucial first month when first impressions mattered most.

**How to Avoid It**:

- ✅ **Plan 6-8 weeks ahead** for custom printed orders (4-5 weeks minimum)

- ✅ **Build in buffer time** for artwork revisions and unexpected delays

- ✅ **Order backup stock** of unprinted bags for emergency situations

- ✅ **Set reorder points** based on usage patterns (typically when inventory drops to 3-4 weeks supply)

- ✅ **Communicate with suppliers** about holiday or peak season delays

**Lead Time Planning Formula**:plaintext

Total Timeline = Artwork (3-5 days) + Proof Approval (2-3 days) +

Production (10-21 days) + Shipping (3-7 days) + Buffer (7 days)

= 25-43 days (4-6 weeks)

**Emergency Options**:

- Keep a backup supplier for plain stock bags

- Establish relationships with local suppliers for rush orders

- Consider digital printing for fast-turnaround needs (1-2 weeks)

[Related: Download our ordering timeline calculator]

---

### Mistake #4: Choosing the Cheapest Option Without Quality Verification

**The Problem**:\

Focusing solely on lowest price often results in thin, weak bags that tear easily, frustrating customers and damaging brand reputation.

**Real Example**:\

A grocery store switched to a supplier offering bags 30% cheaper than their previous source. Customer complaints skyrocketed due to bags tearing, and the store lost an estimated $15,000 in customer goodwill and had to reorder from their original supplier.

**How to Avoid It**:

- ✅ **Compare basis weight** (paper thickness) between suppliers—don't assume "grocery bag" means the same quality

- ✅ **Request third-party certifications** (FSC, FDA compliance) to ensure legitimate manufacturing

- ✅ **Check reviews and references** from businesses with similar use cases

- ✅ **Calculate total cost of ownership** including bag waste/double-bagging, customer satisfaction impact, and reputational damage

- ✅ **Test competitor samples** side-by-side with your current choice

**Quality Red Flags**:

- ❌ Suspiciously low prices (50%+ below market rate)

- ❌ Supplier unable to provide certifications

- ❌ Vague product descriptions without specific basis weight

- ❌ No sample policy or resistance to sending samples

- ❌ Poor communication or delayed responses

**True Cost Analysis**:plaintext

Cheap Bag Option:

Quality Bag Option:

The “cheaper” option actually costs more when accounting for bag failures and lost customer trust.

The Problem:\

Businesses order based on current needs without accounting for growth, seasonal spikes, or promotional events, leading to costly rush reorders at premium prices.

Real Example:\

A restaurant ordered 5,000 bags expecting 3 months of supply. A positive media review doubled their takeout business within weeks, and they exhausted inventory in 6 weeks. Rush reordering cost 40% more per bag and created 2 weeks without branded packaging.

How to Avoid It:

Seasonal Demand Example (Restaurant):

Recommended Order Strategy:

Inventory Management Tips:

Cost Comparison:

💡 Success Checklist

Before placing your bulk order, confirm:

Addressing these five common mistakes eliminates 80% of first-time buyer problems and sets your business up for packaging success.

A: In terms of upfront cost per unit, yes—brown paper bags typically cost $0.06-0.15 each compared to $0.04-0.06 for plastic bags. However, the total cost of ownership tells a different story:

When factoring in compliance costs and brand value, paper bags often deliver superior ROI within 18-24 months.

A: Weight capacity depends on basis weight (paper thickness) and bag construction:

Important factors affecting capacity:

Testing recommendation: Always conduct real-world load tests with your specific products before bulk ordering. A properly specified paper bag can hold as much as or more than plastic alternatives while providing better customer experience.

A: Absolutely! Custom printing is one of the biggest advantages of brown paper bags. Customization options include:

Printing methods:

Minimum order quantities:

Design elements you can include:

Timeline: Custom printed bags typically require 3-4 weeks from artwork approval to delivery. Plan accordingly for seasonal promotions or business launches.

[Related: View our custom printing design guide and examples]

A: Yes, brown paper bags are naturally biodegradable and compostable:

Decomposition timeline:

Composting instructions for customers:

Certifications:

Important note: Bags with heavy plastic coatings, plastic handles, or certain inks may not be compostable. For 100% compostable options, request bags with:

A: Both appear brown, but differ in production process, performance, and environmental profile:

Kraft Paper Bags (Virgin Material):

Recycled Brown Paper Bags (Post-Consumer Content):

Performance comparison:

Environmental considerations:

Recommendation: Choose kraft for premium brands where appearance and strength are paramount. Choose recycled for cost-conscious operations or when emphasizing post-consumer recycled content in sustainability messaging.

A: Proper storage extends bag lifespan and maintains quality:

Environmental conditions:

Storage best practices:

Shelf life:

Space planning:

Signs of improper storage:

Quick storage audit:\

Check your bag storage area monthly for temperature, humidity, and physical condition. Address issues immediately to prevent inventory loss.

Brown paper bags represent far more than simple packaging—they’re a strategic business decision that impacts your bottom line, brand perception, and environmental responsibility. As we’ve explored throughout this comprehensive guide, the advantages are compelling:

Key Takeaways:

✅ Environmental Leadership: Paper bags decompose 120x faster than plastic and maintain an 80% recycling rate, dramatically reducing your business’s environmental footprint.

✅ Cost-Effective at Scale: While initial per-unit costs may be 20-30% higher than plastic, bulk ordering, regulatory compliance savings, and brand value deliver superior ROI within 18-24 months.

✅ Brand Differentiation: Custom-printed bags transform every purchase into a mobile marketing opportunity, generating 3,000+ brand impressions per bag and increasing customer loyalty by 15-23%.

✅ Regulatory Compliance: With plastic bag bans expanding to 17 states and 400+ municipalities, paper bags eliminate regulatory risk and position your business as forward-thinking.

✅ Customer Preference: 78% of consumers actively prefer businesses using sustainable packaging, with Gen Z and Millennials driving this trend even stronger.

Your Next Steps:

The transition to brown paper bags doesn’t need to be overwhelming. Start with these actions:

Ready to Make Your Packaging Work Harder for Your Brand?

Brown paper bags aren’t just containers—they’re ambassadors for your business, silent salespeople carried through your community, and tangible proof of your commitment to quality and sustainability. Every bag tells your brand story and influences how customers perceive your business.

The businesses thriving today recognize that packaging decisions are marketing decisions. They understand that the extra $0.03 per bag is an investment in customer relationships, brand equity, and long-term profitability.

Don’t wait for regulatory mandates or customer backlash to force the change. Lead your industry by making the smart switch now.

🎁 Exclusive Offer: Free Sample Pack + Consultation

Experience the quality difference firsthand. Request our complimentary sample pack including:

Zero obligation. Zero pressure. Just smart business insights.

[Request Your Free Sample Pack] [Schedule Expert Consultation]

Questions? Call our packaging specialists at+86 15057512735or email [email protected]. We’re here to help you make the perfect choice for your business.

[Related Reading: Complete Guide to Sustainable Food Packaging Solutions]\

[Explore: Custom Paper Cup Options for Coffee Shops and Restaurants]\

[Download: 2025 Packaging Trends Report for Retail & Food Service]