Last Updated: November 2025

Reading Time: 8-10 minutes

Author: Papacko Content Team

In the competitive world of healthy fast-casual dining, packaging is more than functional—it’s a sales tool. Salads packaged in opaque containers hide their vibrant colors, fresh ingredients, and generous portions. But salad bowls with transparent window lids turn packaging into a visual merchandising asset, increasing impulse purchases by up to 34% according to retail psychology studies.

This guide explores how window-lid salad packaging influences consumer behavior, compares design options for maximum visibility, and provides sourcing strategies for businesses ranging from health-focused cafés to meal-prep delivery services.

In this article, you’ll learn:

•Visual merchandising principles that make window lids effective sales drivers

•Design variations (full window, partial window, shaped cutouts) and their applications

•Material considerations for clarity, recyclability, and food safety

•Customization strategies for branding around transparency

💡 Quick Takeaway: Window lids transform salad packaging from “storage” to “showcase.” Customers see ingredient quality and portion size before purchase, reducing decision hesitation and increasing conversion rates by 20-35% in grab-and-go settings.

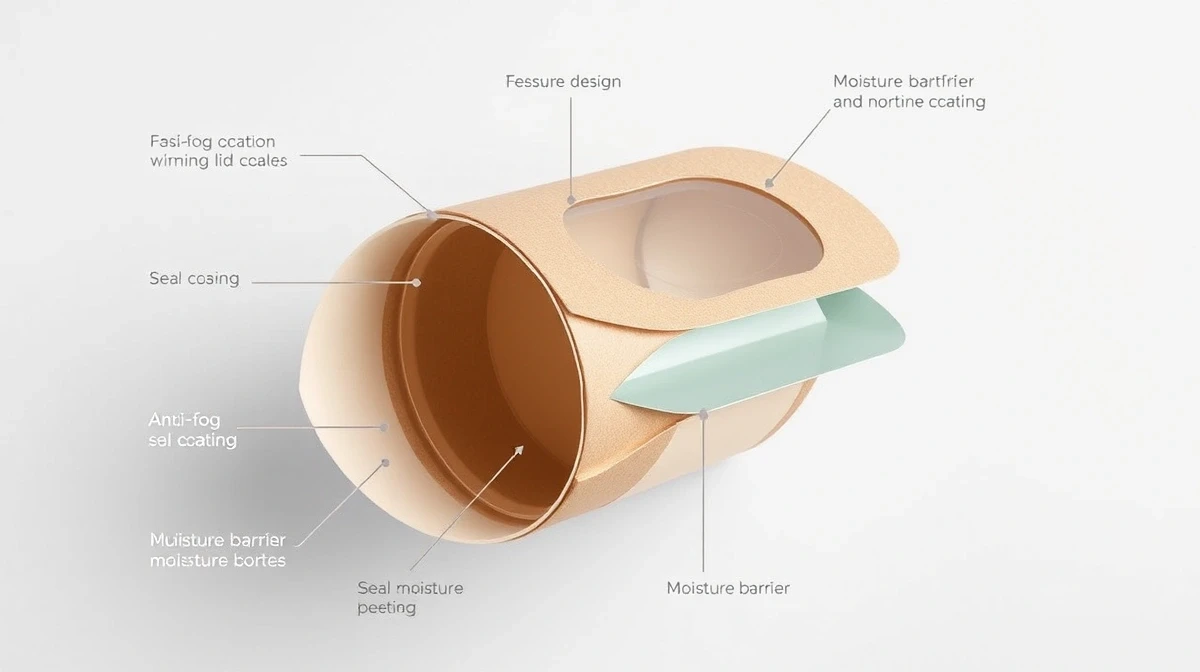

Paper bowls with window lids combine the sustainability of fiber-based containers with the visibility benefits of transparent covers. They typically feature:

•Molded fiber or coated paperboard bowl (kraft or white, 16-32 oz capacity)

•Dual-material lid with transparent window (PET, PLA, or cellulose film) framed by paper/cardboard

•Leak-resistant sealing (snap-fit, friction-fit, or heat-sealed depending on design)

•Anti-fog coatings (optional) to maintain visibility under refrigeration

Primary Use Cases:

Consumer Perception Advantages:

•Freshness Verification: Customers visually confirm ingredient quality before purchase

•Portion Transparency: Visible portion size reduces perceived value uncertainty

•Color Appeal: Vibrant vegetables, greens, and toppings trigger appetite response

•Trust Building: Transparency signals confidence in product quality

🎯 Industry Insight: Restaurants that switched from opaque to window-lid salad containers reported 28% increase in salad sales and 41% fewer customer questions about ingredients/portion sizes.

Appetite Activation Through Color:

Research in food psychology shows specific color combinations trigger stronger purchase intent:

Key Finding: Multi-color salads benefit most from full window lids, while single-tone bowls may perform better with partial windows that incorporate branded photography.

Transparency reduces “blind purchase” hesitation:

•Opaque container: 47% of customers uncertain about value-for-money

•Window lid container: 18% uncertain (61% reduction in doubt)

Portion Perception Experiments:

Insight: Full transparency creates slight overestimation of portion size, which correlates with higher purchase conversion.

Construction:

•Material: PET, PLA, or OPS plastic dome or flat lid

•Frame: Minimal paper rim (5-10mm) for structural support

•Sealing: Snap-fit or friction-fit to bowl lip

Advantages:

•Maximum Visibility: Entire salad composition visible

•360° Viewing: Customers can assess from multiple angles

•Color Impact: Optimizes visual appeal of multi-ingredient salads

Limitations:

•Branding Space: Limited to small top label or bowl body printing

•Structural Integrity: Requires thicker plastic (0.4-0.6mm) for rigidity

•Sustainability Perception: High plastic visibility may concern eco-conscious customers

Best For:

•Premium salad bars with complex ingredient layers

•Self-service display cases where products compete visually

•Businesses prioritizing ingredient quality showcase over branding

Construction:

•Material: Paperboard lid with central transparent window (PET/PLA insert)

•Frame: Structural paper provides branding surface

•Sealing: Secure snap-fit with moisture-resistant coating

Advantages:

•Balanced Visibility + Branding: Window showcases key ingredients while paper frame carries logo/graphics

•Better Sustainability Story: More paper, less plastic by mass

•Structural Versatility: Paper rim adds rigidity and stacking stability

Design Optimization:

Best For:

•Quick-service restaurants balancing branding and transparency

•Franchise operations requiring consistent logo placement

•Products where top-layer ingredients (proteins, toppings) are key selling points

Construction:

•Material: Fully paperboard lid with die-cut window shapes (PET/PLA film backing)

•Design: Custom shapes (leaf, circle, brand logo silhouette)

•Sealing: Film adhered to underside of paperboard for smooth exterior

Advantages:

•Brand Differentiation: Unique window shapes create visual signature

•Storytelling: Leaf-shaped windows emphasize sustainability/natural ingredients

•Cost Efficiency: Less transparent material than full windows

Popular Shapes:

Best For:

•Brands with strong visual identity seeking differentiation

•Organic/natural food concepts emphasizing sustainability

•Limited product lines where packaging recognition is valuable

Selection Criteria:

Choose PET if:

•Your market has strong PET recycling infrastructure

•Crystal clarity is essential for product differentiation

•Cost optimization is priority

Choose PLA if:

•You have industrial composting partnerships

•Customers prioritize “plastic-free” messaging (despite technical nuances)

•Willing to invest in sustainability premium

Choose Cellulose Film if:

•You want full home-compostability

•Can accept slight color tint

•Target premium eco-conscious segment

Problem: Refrigerated salads create condensation on cold lids, obscuring visibility.

Solutions:

Recommendation: For grab-and-go salads held <24 hours, anti-fog coating on PET windows provides best visibility ROI. For longer shelf life (meal prep, retail distribution), combine coating with moisture-absorbing inserts.

Branding Surface Allocation:

Design Best Practices:

1. Maximize Bowl Body Branding:

Since the window showcases the salad, the bowl exterior becomes your primary branding canvas:

•Full-wrap design: Maintains brand visibility from all angles

•High-contrast colors: Ensures recognition in crowded display cases

•Vertical brand elements: Readable even when stacked

2. Strategic Lid Frame Design:

The paper portion of the lid should complement, not compete with, product visibility:

•Top-center logo: 30-50mm diameter, doesn’t obscure window

•Border messaging: Taglines, sustainability icons along lid rim

•Negative space: Avoid cluttering—let window do the selling

3. Interior Printing for Storytelling:

Print on the bowl’s interior base to deliver messages visible only after purchase:

•Ingredient sourcing stories: “Organic kale from [Farm Name]”

•Nutritional highlights: Macro callouts, calorie info

•Brand appreciation: “Thanks for choosing [Brand]”

Case Study Examples:

Differentiation Through Consistency:

Using the same window shape across all salad sizes creates:

•Instant Recognition: Customers identify your product from across the room

•Shelf Presence: Consistent design creates visual “block” in retail displays

•Photography Appeal: Social media posts feature recognizable packaging silhouette

Depth vs. Diameter Trade-offs:

Recommendation: For display-case grab-and-go, prioritize wide & shallow to maximize ingredient spread visibility. For meal delivery/prep, choose narrow & deep for efficient stacking and transport.

Recycling Reality:

Problem: Multi-material lids require consumer separation for proper recycling—but compliance rates are typically <15%. Solutions:

1.Clearly Labeled Separation Instructions: “Peel window from lid before recycling”

2.Mono-Material Designs: Fully transparent PET lids (sacrifice branding space for recyclability)

3.Compostable Systems: Fully compostable paperboard + cellulose window (higher cost)

Marketing Strategy: Display most recognizable certification (FSC, “Plastic-Free”) prominently on bowl body; place technical certifications (BPI) on lid underside for informed customers.

Customization Add-Ons:

### Lead Times and Inventory Planning

Standard Stock vs. Custom:

Seasonal Demand Management:

•Summer peak (salads): Order 6-8 weeks ahead to avoid premium pricing during supplier busy season

•Safety stock: Maintain 3-4 weeks on-hand inventory for custom designs (longer reorder cycles)

❌ Mistake #1: Choosing opaque lids to save costs on window materials

✅ Correct Approach: A/B test window vs. opaque lids—most businesses see 20-35% sales lift that far exceeds 15-25% packaging cost increase

❌ Mistake #2: Maximizing window size without considering condensation

✅ Correct Approach: For refrigerated display >4 hours, invest in anti-fog coating or accept 70-80% window (vs. 100%) to balance visibility and functionality

❌ Mistake #3: Over-branding the lid frame, obscuring product view

✅ Correct Approach: Limit lid graphics to small logo/icon—let the salad sell itself through the window

❌ Mistake #4: Using PLA windows without verifying composting infrastructure

✅ Correct Approach: Audit local waste management capabilities; if industrial composting unavailable, choose recyclable PET instead

Paper bowls with window lids combine fiber-based containers (molded paper or coated paperboard) with transparent-window lids (PET, PLA, or cellulose film framed by paperboard). They allow customers to see salad ingredients while maintaining eco-friendly packaging positioning.

Yes. Studies show 20-35% sales increases when switching from opaque to window-lid containers in grab-and-go settings. Transparency reduces purchase hesitation and visually showcases ingredient quality and portion size.

70-100% window coverage drives highest sales for multi-ingredient salads. However, 50-70% partial windows balance visibility with branding space and may perform better for products where brand recognition is critical.

It depends. PET windows with paperboard frames are recyclable if consumers separate components (compliance rates typically <15%). Mono-material PET lids are easier to recycle. PLA windows contaminate recycling and require industrial composting.

Anti-fog coatings applied to PET or PLA windows maintain clarity for 24-48 hours under refrigeration. Combine with temperature-controlled display cases (2-4°C) and moisture-absorbing inserts for longer shelf life products.

Window lids cost 15-35% more than opaque paperboard lids, depending on window size and material. For a 32oz bowl, expect $0.48-0.85 per unit vs. $0.35-0.55 for opaque equivalents (1000+ quantity pricing).

Yes, but requires higher MOQs (20,000+ pieces) and tooling costs ($500-$2,000) for custom die-cutting. Standard shapes (circle, rectangle, oval) are available at lower MOQs from most suppliers.

Paper bowls with window lids represent the intersection of sustainable packaging and visual merchandising. By transforming opaque containers into product showcases, they address consumer demands for transparency while maintaining eco-friendly credentials through paper-based materials.

Key Takeaways:

1.Window lids increase sales 20-35% in grab-and-go settings by reducing purchase hesitation and showcasing quality

2.Optimal window coverage is 70-100% for multi-ingredient salads; 50-70% for branding-focused strategies

3.PET windows offer best clarity and recyclability; PLA suits industrial composting markets

4.Anti-fog coatings are essential for refrigerated display lasting >4 hours

5.Balance branding and transparency: Let the product sell itself through the window; use bowl body for primary branding

Whether you operate a health-focused café, meal prep service, or grocery salad bar, window-lid packaging investments typically pay back within 3-6 months through increased sales volume and reduced customer service inquiries about portion sizes and ingredients.

•Sustainable Packaging Solutions

Papacko manufactures custom paper bowls with window lids designed for maximum product visibility and sustainable materials. Our solutions include anti-fog PET and compostable PLA window options, custom window shapes, and full-color printing starting at 5,000 pieces.

Get in touch:

Last Updated: November 2025