Last Updated: November 2025

Reading Time: 8 minutes

Author: Papacko Content Team

“Just throw it in the paper recycling bin.” Your customer drops their coffee cup in the blue bin. But that cup won’t be recycled. The PE plastic coating makes it impossible for standard recycling facilities to process.

99% of paper cups end up in landfills despite appearing recyclable. The thin plastic liner that makes cups waterproof also makes them incompatible with paper recycling systems. But specialized facilities exist, and new technologies are changing the landscape.

In this guide, you’ll learn:

•Why standard recycling facilities reject paper cups (PE coating separation problem)

•Specialized cup recycling programs that actually work

•Alternative materials: PLA cups and water-based coatings

•What cafés and restaurants can do today

•Future technologies making recycling easier

💡 Quick Takeaway: PE-coated paper cups can’t be recycled in standard facilities (coating doesn’t separate). Only 1-2% of paper cups globally are recycled through specialized programs. PLA cups require commercial composting, not recycling. Best solution: reusable cups, then compostable cups if infrastructure exists.

What’s Inside Every Standard Paper Cup:

•Outer layer: Paper (180-280gsm paperboard)

•Inner coating: Polyethylene (PE) plastic film (15-25gsm)

•Purpose: Waterproof barrier to prevent liquid soaking through paper

Why This Causes Recycling Problems:

Paper Recycling Process:

1.Paper products mixed with water to create pulp slurry

2.Agitation breaks down paper fibers

3.Screening removes contaminants (plastic, metals)

4.Pulp reformed into new paper products

PE Coating Doesn’t Break Down:

•PE plastic bonds to paper fibers at molecular level (heat-laminated during manufacturing)

•Standard pulping process (60-80°C water) can’t separate PE from paper

•PE contamination ruins entire batch of recycled paper

•Result: Recycling facilities reject paper cups to protect output quality

Contamination Impact:

•One bale of cups (500-1,000 cups) can contaminate 10-20 tons of recycled paper

•Paper mills penalize recycling facilities for contaminated loads ($500-2,000 per contaminated batch)

•Most facilities explicitly ban paper cups in recycling bins

PE Coating Weight:

•Typical paper cup: 5-10% of total weight is PE plastic

•12oz cup: ~10g total, ~0.8g PE plastic

•Annual US cup usage: 120 billion cups = 96,000 tons of PE plastic waste

Separation Requirements:

•Must remove 99.5%+ of PE to meet recycled paper quality standards

•Standard recycling: Achieves only 30-50% PE removal (insufficient)

•Specialized equipment: Can achieve 95-98% removal (acceptable but expensive)

Why Standard Facilities Don’t Upgrade:

•Specialized equipment: $500,000-2 million per facility

•Paper cups represent <1% of total recyclable paper volume

•Economics don’t justify investment for most facilities

•Easier to reject cups than contaminate batches

Advanced Separation Technology:

Hydrapulper with Screening:

•Higher temperature (80-95°C) softens PE coating

•Aggressive agitation separates plastic from fiber

•Fine screening filters out PE fragments

•Process time: 45-60 minutes (vs 15-20 for normal paper)

Flotation Separation:

•Chemical additives cause PE to float to surface

•Skimming removes plastic layer

•Clean paper fiber sinks and is recovered

•Efficiency: 95-98% PE removal

Centrifugal Separation:

•High-speed spinning separates materials by density

•PE (lighter) separates from paper fiber (heavier)

•Used in combination with hydrapulping

•Most effective method for cup recycling

Output:

•Recycled paper fiber (used for tissue, paperboard, insulation)

•PE plastic (typically not recycled further, sent to energy recovery)

United Kingdom:

Simply Cups (Nationwide Program):

•Collects cups from cafés, offices, events

•Processes 4 million cups annually (2024)

•Converts cups to plastic lumber, plant pots

•Collection: Businesses request collection bins

•Cost: Free for large volumes (500+ cups/week), fee for small volumes

ACE UK (Alliance for Beverage Cartons and the Environment):

•Operates 5 specialized cup recycling facilities

•Processes cups into tissue paper, paperboard

•Collection through waste management companies

•Accepts: Coffee cups, juice cartons with similar construction

Costa Coffee / Veolia Partnership:

•2,000+ Costa locations offer cup recycling bins

•Veolia collects and processes at dedicated facility

•Recycled into tissue paper, napkins

•Closes loop: Recycled cups become Costa napkins

United States:

Limited Availability:

•Only 2-3 facilities nationwide process paper cups at scale

•Footprint (fiber products company): Accepts cups at select locations

•Requires clean, dry cups (no liquids, lids separated)

•Minimum volume requirements (not practical for individual cafés)

Starbucks / Closed Loop Partners:

•NextGen Cup Challenge developing recyclable/compostable cup solutions

•Pilot programs in select cities (San Francisco, New York)

•Testing new coating technologies

•Not yet available at scale

Europe:

Germany:

•Paper cup recycling available in 30+ cities

•Yellow bin (packaging) in some regions accepts cups

•Lower recycling rate than UK (5-10% of cups)

Netherlands:

•Starbucks + Huhtamaki program

•Collects cups from 230+ stores

•Recycles into new paper products

•Reusable cup incentive program (€0.25 discount)

Scandinavia:

•High recycling awareness, but limited cup-specific infrastructure

•Focus shifted to reusable and compostable alternatives

•Sweden: Deposit return schemes for reusable cups

Economic Challenges:

•Specialized equipment cost: $500,000-2 million per facility

•Operating cost: 3-5× standard paper recycling

•Market value of recycled fiber: Lower than virgin fiber (PE contamination reduces quality)

•Collected cups must be clean, dry (liquid contamination adds cost)

Logistics Challenges:

•Cups are low-density (large volume, low weight = high transportation cost)

•Must aggregate large volumes to justify processing

•Requires separate collection (can’t mix with standard recycling)

Contamination Challenges:

•Customers put lids, sleeves, straws in cup recycling bins

•Liquid residue adds weight, reduces fiber quality

•Food waste contamination (lipstick, coffee oils)

Break-Even Requirements:

•Facility needs 20-50 million cups annually to operate profitably

•Requires consistent supply (contracts with major chains)

•Small independents can’t access these programs easily

Material: Polylactic acid (plant-based bioplastic) replaces PE coating

Recyclability: ❌ Cannot be recycled in paper recycling

•PLA contaminates recycling like PE

•Looks like plastic to sorting equipment

•Sent to landfill if put in recycling

Correct Disposal: Commercial composting only

•Requires 140-160°F for 90-180 days

•Home composting insufficient (too cold)

•If no commercial composting available → landfill (no better than PE)

Environmental Benefit:

•Compostable in 90-180 days (vs 20-30 years for PE in landfill)

•Plant-based (renewable) vs petroleum-based

•But only if properly composted

Availability: 185 commercial composting facilities in US accept PLA cups (as of 2024)

Use Case: Cities with commercial composting infrastructure (San Francisco, Portland, Seattle)

Material: Aqueous dispersion coating (water-based barrier) replaces PE

Recyclability: ✅ Can be recycled in standard paper recycling

•Coating breaks down during pulping process

•No plastic contamination

•Accepted by most paper recycling facilities

Performance Limitations:

•Heat resistance: 140-160°F max (vs 212°F for PE)

•Not suitable for very hot coffee (185°F+)

•Works for: Warm coffee (165°F), cold drinks, tea

Availability:

•Limited suppliers (emerging technology)

•20-30% cost premium vs PE cups

•Growing adoption in eco-conscious markets

Environmental Benefit:

•Truly recyclable with paper stream

•No plastic waste

•Renewable coating materials

Use Case: Businesses serving warm (not boiling hot) beverages, markets with strong recycling infrastructure

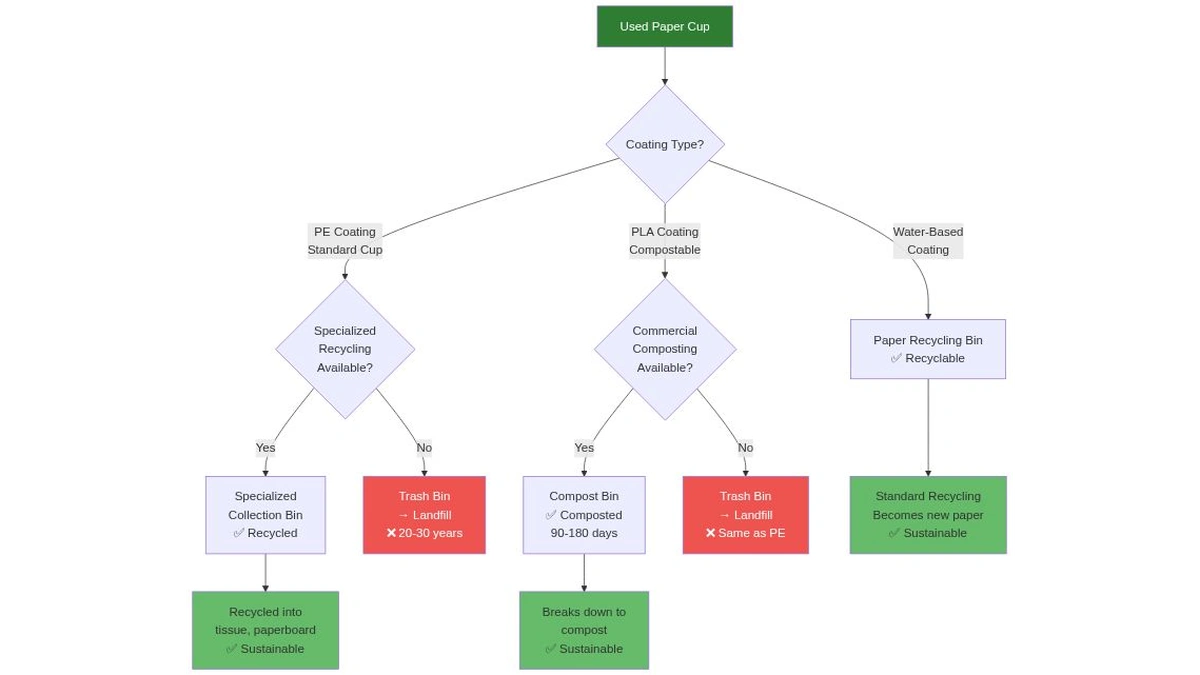

Alt Text: Decision tree showing paper cup disposal options based on coating type and available infrastructure

Filename: blog_011_mermaid_01.png

Discount for Reusables:

•Offer $0.25-0.50 discount for customer’s own cup

•Typical adoption: 15-30% of customers

•Annual savings (café selling 500 cups/day at 20% reusable rate): 36,500 cups saved

In-House Reusable Options:

•Ceramic mugs for dine-in (standard practice)

•Deposit-return reusable cups for takeout ($1-2 deposit)

•Cup-sharing programs (ReCircle, Returnr, CupClub in select cities)

Implementation:

•Train staff on hygiene (clean customer cups thoroughly)

•Clear signage promoting discount

•Track adoption rate (monitor impact)

Cost-Benefit:

•Lost revenue from discount: $0.25 × 100 cups/day = $25/day

•Savings from disposable cups: $0.10 × 100 cups = $10/day

•Net cost: $15/day ($5,500/year) for 100 reusable cups/day

•Marketing value: Positive brand perception offsets cost

Water-Based Coated Cups:

•Cost premium: +20-30% vs PE cups

•Benefit: Truly recyclable (standard bins)

•Best for: Warm coffee service (165-170°F)

PLA Compostable Cups:

•Cost premium: +30-50% vs PE cups

•Benefit: Compostable (commercial facility required)

•Best for: Cities with commercial composting

Decision Criteria:

•Does your city have commercial composting? → Consider PLA

•Do you serve very hot coffee (180°F+)? → Consider water-based if willing to lower temp, or stick with PE + reusable program

•Is recycling infrastructure strong? → Water-based coated cups best option

UK Cafés:

•Sign up for Simply Cups collection (free for 500+ cups/week)

•Partner with local waste management offering cup recycling

US Cafés:

•Check if local Starbucks partnerships exist (Closed Loop Partners)

•Contact Footprint for commercial cup recycling (minimum volumes apply)

Requirements:

•Separate collection bins (cups only, lids removed)

•Staff training (sorting waste correctly)

•Minimum volume (typically 500-1,000 cups/week)

Cost: Often free for large volumes, $50-150/month for smaller volumes

In-Store Signage:

•“Reusable cup? Get $0.25 off!”

•“Our cups are compostable – dispose in green bin”

•“Cup recycling bin – lids and sleeves separate, please”

On-Cup Messaging:

•Print disposal instructions directly on cups

•“Compost me!” or “Recyclable in specialized programs”

•Include QR code linking to local recycling info

Staff Training:

•Explain why standard recycling doesn’t accept PE cups

•Promote reusable cup benefits

•Guide customers to correct disposal bins

Social Media:

•Share sustainability initiatives

•Educate followers on cup recycling challenges

•Highlight reusable cup adoption rate

Track Metrics:

•Reusable cup adoption rate (% of total cups)

•Disposable cups saved annually

•Waste diversion rate (recycled or composted vs landfill)

Report Progress:

•Annual sustainability report (share with customers)

•“Last year we saved 50,000 disposable cups through reusables”

•Transparency builds customer trust

Set Goals:

•Target: 30% reusable adoption by end of year

•Target: 100% compostable or recyclable cups by 2026

•Public commitment drives accountability

Improved Separation Methods:

•Plasma pyrolysis: Breaks down PE coating at molecular level (pilot testing)

•Enzymatic treatment: Biological enzymes dissolve PE (research stage)

•Microwave-assisted separation: Heats PE preferentially, easier removal (limited deployment)

Timeline: 3-5 years before widespread commercial availability

New Coating Technologies:

•Recyclable barrier coatings: Water-based coatings matching PE heat resistance (160-180°F range)

•No-coating designs: Double-wall air-gap insulation (no liquid barrier needed for short service)

•Plant-based coatings: Algae, seaweed-based alternatives (biodegradable + recyclable)

Timeline: Entering market now, mainstream in 2-3 years

Packaging-as-a-Service Models:

•Returnr, CupClub: Reusable cup sharing schemes with app-based tracking

•Deposit systems: Automated kiosks for cup return (Germany, Netherlands)

•Circular economy models: Producers responsible for end-of-life (Extended Producer Responsibility laws)

Timeline: Expanding in Europe, pilot programs in US/Australia

Extended Producer Responsibility (EPR):

•Manufacturers pay for end-of-life recycling

•Incentivizes recyclable design

•Implemented: EU, Canada (some provinces), California (starting 2027)

Single-Use Plastic Bans:

•Includes PE-coated cups in some jurisdictions

•Forces switch to compostable or reusable

•Active: EU, Canada, Australia (state-level), US (city-level: San Francisco, Seattle)

Mandatory Recycling Infrastructure:

•Requirements for specialized cup recycling facilities

•Government subsidies for recycling investment

•Active: UK, EU (under discussion)

Impact: Expect significant increase in cup recycling availability and recyclable cup options by 2030.

Generally NO (for standard PE-coated cups):

•Check with your local recycling program first (call or check website)

•95%+ of programs reject paper cups (PE coating contamination)

•Putting cups in recycling contaminates other recyclables

Exceptions:

•Some UK regions accept cups (check local council)

•Water-based coated cups ✅ (if your café uses these)

•PLA cups ❌ (compost only, not recycling)

Best practice: Assume NO unless your program explicitly states they accept paper cups.

Plastic Lids:

•Usually #6 PS (polystyrene) or #5 PP (polypropylene)

•Check local recycling: Many programs reject #6, some accept #5

•If accepted, rinse and put in plastic recycling (separate from cup)

Paper Sleeves:

•✅ Recyclable with paper (no coating)

•Remove from cup, put in paper recycling bin

Stir Sticks:

•Wooden ✅: Compost or trash

•Plastic ❌: Usually too small for recycling (trash)

Best practice: Separate all components at disposal (cup → specialized bin or trash, lid → plastic recycling if accepted, sleeve → paper recycling).

Standard Starbucks Cups: PE-coated, ❌ not recyclable in most programs

Exceptions:

•Select locations: Starbucks has cup recycling bins in 3,000+ stores (mostly US, UK)

•Cups collected are sent to specialized facilities

•This is a specialized program, not standard recycling

Outside Starbucks locations: Still not recyclable in home bins

Starbucks Alternatives:

•Reusable cups accepted (customer provides)

•$0.10 discount for reusables (US, varies by region)

•Reusable cup sold in-store

Future: Starbucks committed to fully recyclable or compostable cups by 2025 (ongoing trials with water-based and PLA coatings).

Depends on local infrastructure:

Compostable Cups (PLA) ✅ IF:

•Your city has commercial composting accepting PLA

•Customers dispose correctly (compost bin, not trash/recycling)

•Beverage temperature under 160°F

Recyclable Cups (Water-Based) ✅ IF:

•Strong paper recycling infrastructure exists

•Beverage temperature under 165-170°F (warm coffee okay)

•Customers familiar with paper recycling

Neither is Perfect:

•PLA in landfill = no better than PE

•Water-based cups recycled = downcycled (lower quality paper, not circular)

Best Option: Reusable cups (eliminates waste entirely), with compostable/recyclable as backup for customers who won’t use reusables.

Technically yes, but extremely slowly:

PE-Coated Cups:

•Paper component: 6 months to 5 years (depends on landfill conditions)

•PE coating: 20-30 years (plastic doesn’t biodegrade)

•End result: PE plastic remains as microplastics

Landfill Conditions Prevent Degradation:

•Anaerobic (no oxygen) = slow decomposition

•Compacted layers limit moisture and microbial activity

•Items buried in landfills mummify rather than degrade

PLA Cups in Landfill:

•Same as PE (no advantage without composting conditions)

•PLA needs oxygen + heat + moisture to break down

•Landfills lack these conditions

Reality: “Biodegradable” in landfill is largely a myth for both PE and PLA cups.

Specialized Cup Recycling: Generally no

•Programs require clean, dry cups

•Liquid residue adds weight (increases processing cost)

•Coffee oils contaminate recycled fiber

•Rinse cups if possible before disposal

Standard Paper Recycling: Definitely no

•Contamination disqualifies materials

•Soiled paper/cardboard goes to trash

Compostable Cups: Yes

•Commercial composting handles food residue

•No need to rinse before composting

•Food waste + cup compost together

Best practice: Rinse if convenient, but don’t waste excessive water. For compostable cups, no rinse needed.

Global Average: 1-2% of paper cups are recycled

Breakdown by Region:

•United States: <1% (limited specialized facilities)

•United Kingdom: 4-5% (best in world due to Simply Cups and other programs)

•Europe: 2-3% (Germany, Netherlands higher; most countries lower)

•Australia: 1-2% (limited infrastructure)

Why So Low:

•Specialized recycling required (expensive, rare)

•Customer confusion (cups look recyclable)

•Contamination in standard recycling bins

•Economic challenges (recycling costs exceed value)

By Comparison:

•Standard paper/cardboard: 65-75% recycled globally

•Aluminum cans: 70% recycled

•PET plastic bottles: 30-40% recycled

Path Forward: Policy changes (EPR), new coating technologies, and specialized programs expanding could reach 20-30% by 2030.

Paper cup recycling is technically possible but practically rare, requiring specialized facilities most regions lack.

Key Takeaways:

1.PE-coated cups (standard) ❌ can’t be recycled in regular bins (plastic coating contaminates paper recycling)

2.Specialized programs exist but cover only 1-2% of cups globally (UK’s Simply Cups, Starbucks partnerships)

3.PLA compostable cups require commercial composting at 140-160°F (not recyclable, only 185 US facilities accept)

4.Water-based coated cups ✅ are truly recyclable but limited availability and heat constraints (max 165-170°F)

5.Reusable cups are the best solution: 15-30% adoption eliminates millions of disposable cups

6.Future looks better: New coating technologies and EPR policies will improve recycling by 2030

7.Best action for cafés: Reusable cup programs + switching to water-based or PLA cups based on local infrastructure

Check local recycling/composting options before choosing cup type, educate customers, and prioritize reusables.

•Paper Cups – Explore recyclable and compostable cup options

•Eco Paper Cups – FSC-certified and PLA cup specifications

•PLA Cups vs PE Cups – Material comparison guide

Papacko supplies recyclable water-based cups, BPI-certified PLA compostable cups, and FSC-certified paper cups for eco-conscious businesses.

Why choose Papacko:

•Multiple eco options: Water-based recyclable, PLA compostable, FSC-certified

•Infrastructure matching: We help verify local recycling/composting availability

•Heat testing: Samples provided to test with your beverage temperatures

•Disposal guidance: Free signage templates for customer education

•Reusable program support: Consultation on implementing discount programs

•Volume flexibility: Mix recyclable and compostable to meet MOQ (from 50,000 total)

Get in touch:

•Request a Quote – Compare pricing for water-based vs PLA vs standard cups

•Free Sample Kit – Test recyclable and compostable options with your beverages

•Sustainability Consultation – Optimize waste reduction strategy for your business