Last Updated: November 2025

Reading Time: 9 minutes

Author: Papacko Content Team

Takeaway and delivery now make up 40-60% of revenue for many restaurants. Your packaging isn’t just a container anymore — it’s part of the product itself.

The right disposable food packaging keeps food hot (or cold), prevents leaks during transport, maintains presentation, and reinforces your brand identity. Bad packaging? That means soggy fries, spilled sauce, angry customers, and 1-star reviews.

But here’s the thing: not all disposable packaging is created equal. Paper boxes work great for fried chicken but fail miserably for soup. PLA containers look eco-friendly but can’t handle temperatures above 140°F. And that “biodegradable” clamshell might cost 50% more than standard PE-lined alternatives.

In this guide, you’ll learn:

•Which materials actually work for different food types (oil, heat, moisture)

•Real cost breakdowns including hidden expenses

•Leak-proof sealing mechanisms that actually prevent spills

•How to balance sustainability claims with operational reality

💡 Quick Takeaway: The “best” disposable packaging depends on your menu’s temperature range, oil content, delivery time, and customer expectations. A burger needs different packaging than ramen, and premium brands need different packaging than value concepts.

Your packaging is the last thing you control before food reaches the customer. Once it leaves your kitchen, you can’t fix presentation, temperature, or structural integrity.

Most restaurants focus on food cost percentage but ignore packaging impact on customer satisfaction and repeat orders.

What happens with wrong packaging:

•Soggy containers from steam buildup (especially fried foods)

•Sauce leaks staining delivery bags or car seats

•Food arrives cold because container has poor insulation

•Items shift during transport, ruining presentation

•Eco-conscious customers notice greenwashing claims

Business impact:

•23% of delivery complaints relate to packaging issues (leaked sauce, crushed containers, cold food)

•Customers blame the restaurant, not the delivery driver or packaging supplier

•One bad experience frequently means no repeat order, regardless of food quality

Temperature Maintenance: Fried chicken should arrive crispy, soup should stay hot for 20-30 minutes. This requires understanding insulation properties and vent placement.

Structural Integrity: Packaging must survive:

•Stacking in delivery bags (3-5 orders per driver)

•Motorcycle/bicycle vibration and impacts

•Temperature changes (kitchen heat → ambient air → customer location)

•Customer handling (opening without spilling)

Leak Prevention: The #1 complaint in food delivery. Requires:

•Proper seal design (tab locks vs pressure fit vs adhesive)

•Grease-resistant barriers (15-25gsm coating minimum)

•Liquid compartment isolation for sauces/dressings

Brand Communication: Your packaging is mobile advertising. 73% of delivery customers keep containers temporarily (for leftovers, storage), extending brand exposure beyond the meal.

🎯 Industry Insight: Premium fast-casual brands spend 8-12% of food cost on packaging, while value QSR spends 3-5%. The difference shows in customer perception, repeat rates, and average order values.

Best For: Dry/semi-dry foods, sandwiches, burgers, wraps, fried chicken, pizza, baked goods

Material Structure:

•Base paper: 250-350gsm kraft or white paperboard

•Inner coating: PE (petroleum-based) or PLA (plant-based) or water-based barrier

•Grease resistance: 15-25gsm coating thickness

✅ Advantages:

•Lower carbon footprint than plastic alternatives

•Microwave-safe (water-based coating only; PE and PLA are not)

•Better consumer perception for sustainability

•Breathable design prevents steam buildup for fried foods

❌ Limitations:

•Not suitable for high-liquid foods (soups, curries with lots of sauce)

•Heat resistance limited to 185-200°F depending on coating

•More expensive than plastic containers (15-30% premium)

•Can soften or deform with extended contact with moist foods

Typical Specifications:

| Product Type | Paper Weight | Coating Type | Heat Resistance | Best Application |

|---|---|---|---|---|

| Kraft lunch boxes | 300-350gsm | PE or PLA | Up to 200°F | Burgers, sandwiches, salads |

| Paper bowls | 250-280gsm | PE (double layer) | Up to 212°F | Pasta, rice bowls, noodles |

| Clamshell boxes | 280-320gsm | PE or Water-based | Up to 185°F | Fried chicken, tacos, wraps |

| Pizza boxes | 280-300gsm | No coating (breathable) | Up to 300°F | Pizza, flatbreads |

Best For: High-liquid foods, soups, curries, sauces, cold salads, desserts, beverages

Common Types:

•PP (Polypropylene): Heat-resistant, microwave-safe, most versatile

•PET (Polyethylene Terephthalate): Crystal-clear, great for cold items and salads

•PS (Polystyrene/Foam): Excellent insulation, lowest cost, being phased out in many regions

✅ Advantages:

•Excellent liquid containment (zero leaks with proper lid seal)

•High heat resistance (PP handles up to 240°F, safe for microwaving)

•Crystal-clear options (PET) showcase food beautifully

•Lowest cost per unit (30-50% cheaper than paper alternatives)

•Longest shelf life for stored inventory (no moisture sensitivity)

❌ Limitations:

•Poor environmental perception (customers associate plastic with waste)

•Not compostable or easily recyclable in most regions

•Banned or restricted in many cities/countries (especially PS foam)

•Can leach chemicals at high temperatures (verify food-grade certification)

Typical Applications:

| Material | Heat Range | Microwave Safe | Best For | Avg Cost |

|---|---|---|---|---|

| PP (Clear/Black) | -4°F to 240°F | Yes | Hot soups, curries, rice dishes | $0.15-0.25 |

| PET (Crystal clear) | -40°F to 140°F | No | Cold salads, desserts, sushi | $0.12-0.20 |

| PS Foam | 32°F to 200°F | Limited | Budget hot meals (where legal) | $0.08-0.12 |

⚠️ Regulation Alert: Polystyrene foam (Styrofoam) is banned in 100+ cities including NYC, SF, Seattle, and entire states like California, Maine, Maryland. Always verify local regulations before ordering.

Best For: High-heat foods, ovens, catering, family-size portions, frozen meal prep

✅ Advantages:

•Extreme heat resistance (can go directly into oven up to 500°F)

•Excellent heat retention (keeps food hot 45-60 minutes)

•Grease and moisture proof (zero leaks)

•Recyclable in most programs (higher acceptance than mixed-material containers)

•Can be frozen and reheated multiple times

❌ Limitations:

•Not microwave-safe (metal causes sparking)

•Higher cost than paper or plastic (25-40% premium)

•Not transparent (can’t showcase food visually)

•Environmental concerns about mining and production energy

Best Applications: Lasagna, casseroles, roasted meats, family meal kits, catering trays, meal prep services

Not all foods behave the same way during transport. Group your menu items by these characteristics:

High Heat + Low Moisture (Fried/grilled items):

•Fried chicken, french fries, grilled sandwiches, pizza

•Best packaging: Vented paper clamshells or kraft boxes with ventilation holes

•Why: Steam escapes, preventing sogginess; paper absorbs minimal grease

High Heat + High Moisture (Soups, curries, stews):

•Ramen, pho, curry, chili, stews, saucy pasta

•Best packaging: PP plastic containers with secure snap lids + separate sauce cups

•Why: Only plastic reliably prevents leaks; paper softens with prolonged liquid contact

Room Temp + Moderate Moisture (Sandwiches, wraps):

•Deli sandwiches, burritos, wraps, sushi rolls

•Best packaging: Kraft paper boxes or PLA-lined clamshells

•Why: Moderate grease resistance needed; eco-friendly options work well

Cold + High Moisture (Salads, desserts):

•Green salads, grain bowls, poke, desserts

•Best packaging: Clear PET containers with secure lids

•Why: Showcases ingredients; no heat resistance needed; customers want to see freshness

Short delivery (less than 15 minutes):

•Standard single-wall paper or basic plastic works fine

•Cost-effective option for nearby customers

•Steam buildup is minimal

Medium delivery (15-30 minutes):

•Need better insulation for hot foods

•Consider double-wall paper or insulated bags

•Vent placement becomes critical for fried items

Long delivery (30+ minutes):

•Aluminum containers for maximum heat retention

•Separate components (keep crispy items separate from sauce)

•Insulated delivery bags are essential

•Consider active heating solutions for premium service

Don’t just look at the per-unit price. Factor in:

Hidden Costs to Consider:

1.Waste from customer complaints: One leaked container = lost customer + refund + bad review

– Estimated cost: $15-30 per incident

2.Storage space: Bulkier packaging (foam clamshells, large boxes) requires more warehouse space

– Consider: Cost per cubic foot of storage

3.Labor time: Complex assembly (separate lids, tabs, inserts) adds 5-15 seconds per order

– At 200 orders/day: 15-50 minutes of extra labor daily

4.Brand perception: Cheap packaging signals cheap food, even if your food is premium

– Premium packaging can justify 8-12% higher menu prices

Example Cost Comparison (16oz bowl, MOQ 10,000 units):

| Container Type | Unit Cost | Assembly Time | Complaint Rate | True Cost/Unit |

|---|---|---|---|---|

| Basic PP plastic | $0.15 | 3 sec | 2% | $0.17 |

| Kraft paper bowl (PE-lined) | $0.22 | 5 sec | 1% | $0.24 |

| PLA compostable bowl | $0.28 | 5 sec | 1% | $0.30 |

| Aluminum foil container | $0.25 | 4 sec | 0.5% | $0.26 |

💡 Papacko Tip: For high-volume takeaway (500+ orders/day), a 1% reduction in leak complaints saves $75-150 monthly in refunds and redeliveries. Premium packasometimesoften pays for itself through fewer complaints alone.

The #1 delivery complaint worldwide: “The sauce leaked all over the bag.”

Tab Lock Seals (common in clamshells):

•How it works: Tabs on lid fit into slots on base

•Pros: No adhesive needed, easy to open, reusable by customer

•Cons: Can pop open if overfilled or impacted during transport

•Best for: Dry/semi-dry foods (burgers, fries, salads)

•Leak risk: Medium (3-5% failure rate with proper fill levels)

Pressure Fit Lids (common in plastic containers):

•How it works: Lid edge compresses onto container rim, creating seal

•Pros: Strong seal, works with liquids, simple design

•Cons: Can be difficult for customers to open, requires precise manufacturing

•Best for: Soups, curries, liquid-heavy dishes

•Leak risk: Low (less than 1% with quality manufacturing)

Adhesive/Peel Seals (premium option):

•How it works: Heat-sealed film or adhesive strip bonds lid to container

•Pros: Tamper-evident, strongest leak protection, premium perception

•Cons: Not reusable, adds cost ($0.03-0.05 per unit), requires special equipment

•Best for: Meal kits, catering, delivery-only brands

•Leak risk: Very low (less than 0.5%)

Fold-Top Designs (paper bags, boxes with tabs):

•How it works: Flaps fold and tuck or use adhesive closure

•Pros: Simple, economical, works for dry items

•Cons: Not leak-proof, poor for liquids, can open during transport

•Best for: Pizza, sandwiches, baked goods

•Leak risk: High for liquids (not recommended)

Fill Level Management:

•Never fill liquid containers above 80% capacity

•Leave 0.5-1 inch of headroom for seal compression

•For sauces, use separate 2oz/4oz portion cups with secure lids

Separate Wet and Dry Components:

•Package dressing separately for salads (customer adds)

•Keep fried items separate from sauce containers

•Use compartmentalized containers for multi-component meals

Lid Application Training:

•Train staff to press lids firmly around entire perimeter

•Check for visible gaps before bagging order

•Establish quality control spot-checks (1 in 10 orders)

Delivery Bag Positioning:

•Place liquid containers upright in center of bag

•Use dividers or cardboard inserts to prevent shifting

•Instruct drivers to keep bags level during transport

📦 Papacko Quality Standard: Our food containers undergo drop tests from 3 feet with full liquid fill. Containers must maintain seal integrity through 5 consecutive drops to pass inspection.

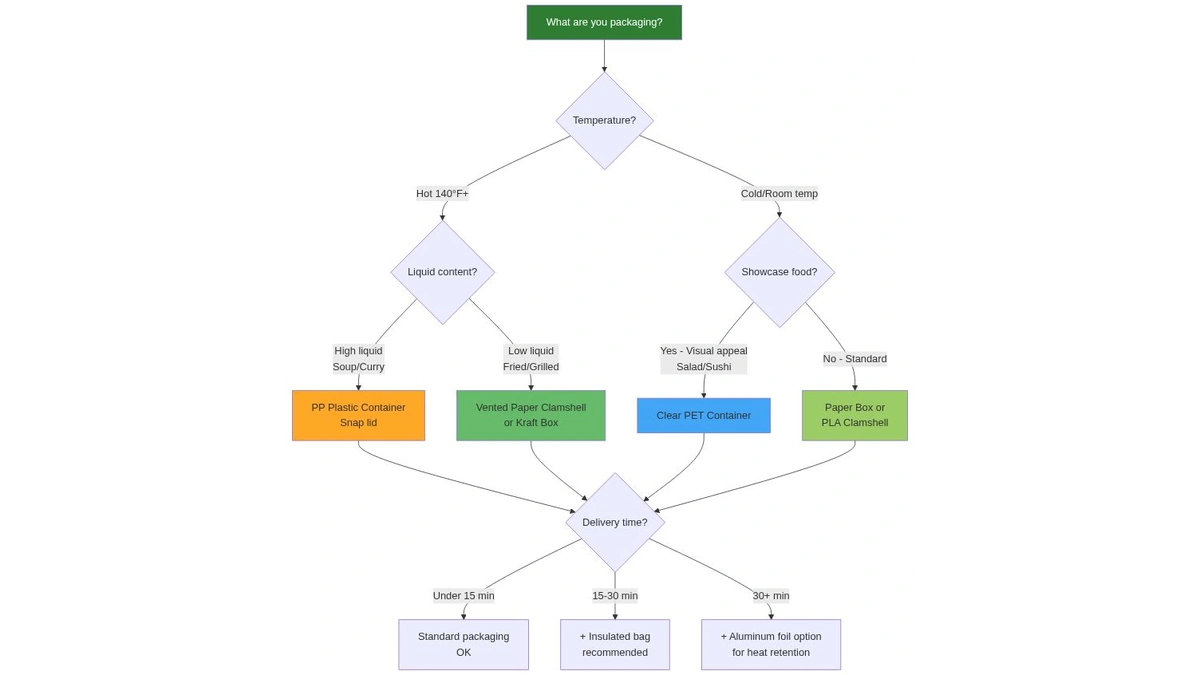

Alt Text: Decision tree for selecting disposable food packaging based on temperature, liquid content, presentation needs, and delivery time

Filename: blog_002_mermaid_01.png

“Compostable” doesn’t mean it will compost in your backyard or local landfill. “Recyclable” doesn’t mean it will actually be recycled.

Truth about PLA (Polylactic Acid) packaging:

•Requires industrial composting facilities at 140-160°F for 90-180 days

•Less than 5% of US municipalities have access to commercial composting

•If sent to landfill, PLA doesn’t decompose any faster than regular plastic

•Can’t be recycled with standard plastics (contaminates recycling streams)

•Costs 20-40% more than PE-coated alternatives

When PLA makes sense:

•You have confirmed access to commercial composting

•Your customers care about sustainability and will pay premium

•Local regulations incentivize or mandate compostable packaging

•You want to build brand identity around environmental responsibility

When PLA doesn’t make sense:

•No local composting infrastructure (ends up in landfill anyway)

•Price-sensitive customer base

•High-heat applications (PLA softens above 140°F)

Option 1: Recyclable Paper with Water-Based Coating

•Can be processed in standard paper recycling streams

•Lower carbon footprint than plastic

•Widely accepted by consumers

•Cost: 20-35% more than PE-coated

Option 2: PP Plastic (Recyclable Plastic #5)

•Many programs now accept PP for recycling

•More durable than paper (fewer wasted containers)

•Longest functional life if customers reuse containers

•Cost: Baseline pricing

Option 3: Reusable Container Programs

•Customers return containers for cleaning and reuse

•Works for dine-in pickup or subscription meal services

•Reduces waste by 90%+ compared to disposables

•Operational complexity: High (cleaning, tracking, logistics)

FSC (Forest Stewardship Council): Paper products from sustainably managed forests

BPI (Biodegradable Products Institute): Certifies compostable products meet ASTM D6400 standards

FDA Approved: Food-contact safety (non-negotiable for all packaging)

PFAS-Free: No per- and polyfluoroalkyl substances (forever chemicals) in coating

♻️ Sustainability Reality Check: The most eco-friendly packaging is the one customers will actually dispose of correctly. Clear labeling (“Recycle with paper” vs “Compost only”) matters more than the material itself.

Problem: Container looks great empty, but fails with real menu items.

Example: Restaurant orders beautiful paper boxes for their signature curry. Boxes soften and leak within 10 minutes because the coating can’t handle the oil content and temperature.

Correct Approach:

•Order samples (50-100 units minimum)

•Test with your actual menu items, not water or generic foods

•Simulate real delivery conditions: pack it, bag it, drive it around for 20-30 minutes

•Have staff and customers open containers to check ease of use

Problem: Container and lid are from different suppliers or production batches. Lids don’t seal properly.

Why This Happens:

•Slight manufacturing tolerance differences (0.5mm matters)

•Mixing old and new inventory with design changes

•Assuming “universal lids” actually fit all containers

Correct Approach: Always order containers and lids together from the same supplier in the same order. Test fit before accepting large shipments.

Problem: New packaging saves $0.02 per unit but requires complex assembly, adding 15 seconds per order.

Real Cost: At 200 orders/day, that’s 50 minutes of labor daily = $250-400/month in labor costs, wiping out savings.

Correct Approach: Time your staff assembling 10 containers. If it takes longer than your current packaging, calculate the labor cost difference.

Problem: Packaging labeled “compostable” but no certification, unclear standards, or no local composting infrastructure.

Greenwashing Red Flags:

•“Biodegradable” without timeframe or conditions specified

•“Eco-friendly” with no actual certification

•“Plant-based” but uses plastic-like coatings

•No BPI, TUV, or third-party certification logos

Correct Approach: Request certifications (BPI, ASTM D6400, EN 13432). Verify that your local waste management accepts the material.

⚠️ Warning: Making false sustainability claims can result in fines, lawsuits, and serious brand reputation damage. The FTC actively pursues greenwashing violations.

| Material Type | Heat Range | Liquid Proof | Microwave Safe | Relative Cost | Best For |

|---|---|---|---|---|---|

| PE-Coated Paper | Up to 200°F | Medium (grease resistant) | No | $$ (baseline +10%) | Burgers, sandwiches, fries |

| PLA-Coated Paper | Up to 140°F | Medium | No | $$$ (+30-40%) | Cold salads, eco-brands |

| PP Plastic | -4°F to 240°F | Excellent | Yes | $ (baseline) | Soups, curries, hot liquids |

| PET Plastic (Clear) | -40°F to 140°F | Excellent | No | $ (baseline) | Cold salads, sushi, desserts |

| Aluminum Foil | -40°F to 500°F | Excellent | No (oven-safe) | $$$ (+25-40%) | Catering, meal prep, ovens |

| Molded Fiber (Bagasse) | Up to 200°F | Low-Medium | Limited | $$ (+15-25%) | Dry foods, eco-conscious brands |

Biodegradable means the material will eventually break down into natural elements. But there’s no standard for how long this takes. It could be 6 months or 500 years. Most “biodegradable” plastics still leave microplastic residue.

Compostable means the material breaks down into nutrient-rich compost within a specific timeframe (most times 90-180 days) under specific conditions. True compostable packaging must meet ASTM D6400 (US) or EN 13432 (EU) standards.

Key difference: Compostable packaging has certified standards and timeframes. Biodegrasometimes is often marketing language without enforcement.

For takeaway packaging, look for BPI-certified compostable containers if you’ve access to commercial composting. Otherwise, recyclable paper or plastic may be more environmentally responsible than “biodegradable” products that end up in landfills.

It depends on the material:

Microwave-Safe:

•PP (polypropylene) plastic containers — Yes, safe up to 240°F

•Some paper containers with water-based coating — Check label

NOT Microwave-Safe:

•PE-coated paper (coating can melt)

•PLA-coated containers (softens at 140°F)

•Aluminum foil containers (causes sparking/fire risk)

•PET plastic (not heat-resistant)

•Any container with metal components or decorative foil

Always label your packaging clearly. If containers aren’t microwave-safe, include heating instructions (“Transfer to microwave-safe dish before reheating”).

Costs vary widely based on material, size, customization, and order quantity.

Typical price ranges (per unit, MOQ 10,000+):

•Budget PP plastic containers (16oz): $0.12-0.18

•Standard paper boxes/bowls (16oz): $0.18-0.28

•PLA compostable containers (16oz): $0.25-0.38

•Aluminum foil containers (16oz): $0.22-0.32

•Custom printed packaging: Add $0.03-0.08 per unit

Volume discounts:

•10,000 units: Baseline price

•50,000 units: 8-15% discount

•100,000 units: 15-25% discount

•500,000+ units: 25-35% discount

Don’t forget hidden costs: lids (add $0.05-0.12), utensils ($0.02-0.04), napkins ($0.01-0.02), bags ($0.05-0.15).

Total packaging cost for average takeaway order: $0.35-0.75.

Minimum order quantities (MOQ) for custom printing:

Standard digital printing: 5,000-10,000 units (higher cost per unit, faster turnaround)

Flexographic printing: 30,000-50,000 units (most cost-effective for volume)

Offset printing: 50,000-100,000 units (best for complex, multi-color designs)

Timeline considerations:

•Design approval and plate-making: 7-10 days

•Production: 15-25 days

•Shipping (if importing from Asia): 30-45 days

•Total lead time: 50-80 days for first order

Cost breakdown (16oz paper bowl, 2-color print, MOQ 50,000):

•Setup fee: $300-600 (one-time)

•Per-unit cost: $0.22-0.28

•Total investment: $11,300-14,600

For startups, consider:

•Starting with stock (unprinted) packaging

•Using stickers/labels for branding (MOQ as low as 500)

•Partnering with suppliers offering mixed-SKU flexibility

Sogginess happens when steam condenses inside sealed containers, making crispy foods soft.

Prevention strategies:

Use vented containers: Small holes or perforations allow steam to escape. Critical for fried foods, pizza, french fries.

Separate components: Pack crispy and moist items in separate compartments or containers. Don’t put dressing on salads or sauce on fried items until customer is ready to eat.

Choose breathable materials: Uncoated kraft paper or paperboard (like pizza boxes) absorbs minimal moisture while allowing air circulation.

Avoid over-packing while hot: Let fried foods cool for 1-2 minutes before sealing. This reduces steam generation.

Use absorbent liners: Place a paper liner at the bottom to absorb excess moisture/oil.

Timing matters: The longer food sits in sealed packaging, the soggier it gets. Optimize kitchen-to-customer time.

For items that must stay crispy (fried chicken, tempura, fries), vented paper clamshells or boxes with ventilation holes are non-negotiable.

Yes. Food packaging must comply with safety standards to prevent chemical migration into food.

United States:

•FDA Title 21 CFR Part 176 (paper and paperboard)

•FDA Title 21 CFR Part 177 (plastics)

•State bans on specific materials (e.g., California banned PS foam)

European Union:

•Regulation (EC) No 1935/2004 (general food contact materials)

•Regulation (EU) No 10/2011 (plastic food contact)

•Restrictions on PFAS (forever chemicals) in coatings

China (for imports/exports):

•GB 4806 series (food contact materials)

•GB/T 27591 (compostable plastics)

Key compliance requirements:

•Migration testing (chemicals can’t transfer to food above limits)

•Heavy metal limits (lead, cadmium in inks/coatings)

•BPA-free certification for plastics

•PFAS-free certification for coatings

Always request certificates of compliance from suppliers. Reputable manufacturers provide:

•Material safety data sheets (MSDS)

•FDA/EU compliance certificates

•Third-party lab test reports

Yes — if operational complexity allows.

Dine-in packaging priorities:

•Visual appeal (showcase food attractively)

•Premium materials (thicker paper, better printing)

•Moderate cost (customers staying in the restaurant)

•Reusable options (some fast-casual concepts use reusable bowls/plates)

Takeaway/delivery packaging priorities:

•Leak-proof seals (survive transport)

•Structural integrity (stacking, vibration resistance)

•Heat retention (food stays hot 20-30+ minutes)

•Ease of opening (customer convenience at home)

•Cost efficiency (higher volume, tighter margins)

Hybrid approach: Use the same base container, but offer premium presentation for dine-in (better plating, garnish, ceramic option) and functional packaging for takeaway (secure lids, tamper seals, insulated bags).

Many restaurants find operational simplicity (one packaging system for all channels) outweighs the benefits of dual systems.

The right disposable food packaging depends on your menu’s specific needs — not generic “best practices” or what competitors use.

Key Takeaways:

1.Match packaging material to food characteristics: high-heat liquids need PP plastic, fried foods need vented paper, cold items can use PET

2.True packaging cost includes assembly labor, complaint rates, and brand perception — not just per-unit price

3.“Eco-friendly” claims require verification: PLA only composts in industrial facilities, not landfills

4.Leak prevention comes from proper seal design, fill levels, and separating wet/dry components

5.Test packaging with actual menu items under real delivery conditions before committing to large orders

Your packaging is the last touchpoint before the customer experiences your food. Invest in getting it right — it directly impacts repeat orders, reviews, and long-term profitability.

Explore more food packaging solutions:

•Food Packaging Containers – Complete range for takeaway and delivery

•Paper Cups & Coffee Packaging – Hot and cold drink solutions

•Packaging Accessories – Lids, utensils, bags, and napkins

Papacko supplies export-ready disposable packaging to restaurants, cloud kitchens, and food service distributors worldwide.

Whether you need trial orders to test with your menu or container-load shipments, we ensure consistent quality, competitive pricing, and on-time delivery.

Why choose Papacko:

•Menu-matched solutions: Help selecting packaging based on your actual food items

•Flexible MOQ: Mixed-size and mixed-material orders from 10,000 units

•Quality assured: FDA, EU, and GB compliance with third-party lab verification

•Custom printing: Full-color branding with 30-35 day lead times

•Reliable logistics: FOB, CIF, or DDP terms available

•Expert support: Dedicated account managers for specification guidance

Get in touch:

•Request a Quote – Contact us for detailed pricing

•Sample Testing Program – Test packaging with your menu before bulk ordering

•Learn more about our export-ready solutions