Last Updated: November 2025

Reading Time: 8-10 minutes

Author: Papacko Content Team

Every coffee shop and quick-service restaurant faces the same challenge: how do customers safely carry 3-6 drinks without spills, discomfort, or awkward balancing acts? Standard single-cup holders and flimsy cardboard trays lead to accidents, customer frustration, and wasted product. The solution lies in ergonomically designed multiple drink holders that distribute weight evenly, prevent tipping, and make group orders convenient.

This guide examines the biomechanics of multi-drink carrying, compares holder designs from 2-cup to 6-cup configurations, and provides sourcing strategies for businesses ranging from drive-thru coffee chains to catering operations.

In this article, you’ll learn:

•Ergonomic principles that prevent strain and spillage when carrying multiple beverages

•Design variations (2-cup, 4-cup, 6-cup) and structural features for stability

•Material choices balancing strength, sustainability, and cost

•Customization opportunities for branding high-visibility accessories

💡 Quick Takeaway: Poorly designed drink holders cause 15-20% of all beverage spills during transport.

Ergonomically optimized carriers with center-of-gravity balance, reinforced handles, and cup-size adaptability reduce spills to <3% while improving customer satisfaction scores by 18-24%.

Multiple drink holders (also called cup carriers, drink trays, or beverage caddies) are portable containers designed to secure and transport 2-6 cups or bottles simultaneously. They feature:

•Individual cup slots with tapered or molded supports to prevent shifting

•Reinforced handle(s) positioned to balance loaded weight

•Foldable or stackable construction for efficient storage

•Moisture-resistant materials to prevent structural failure from condensation

Common Configurations:

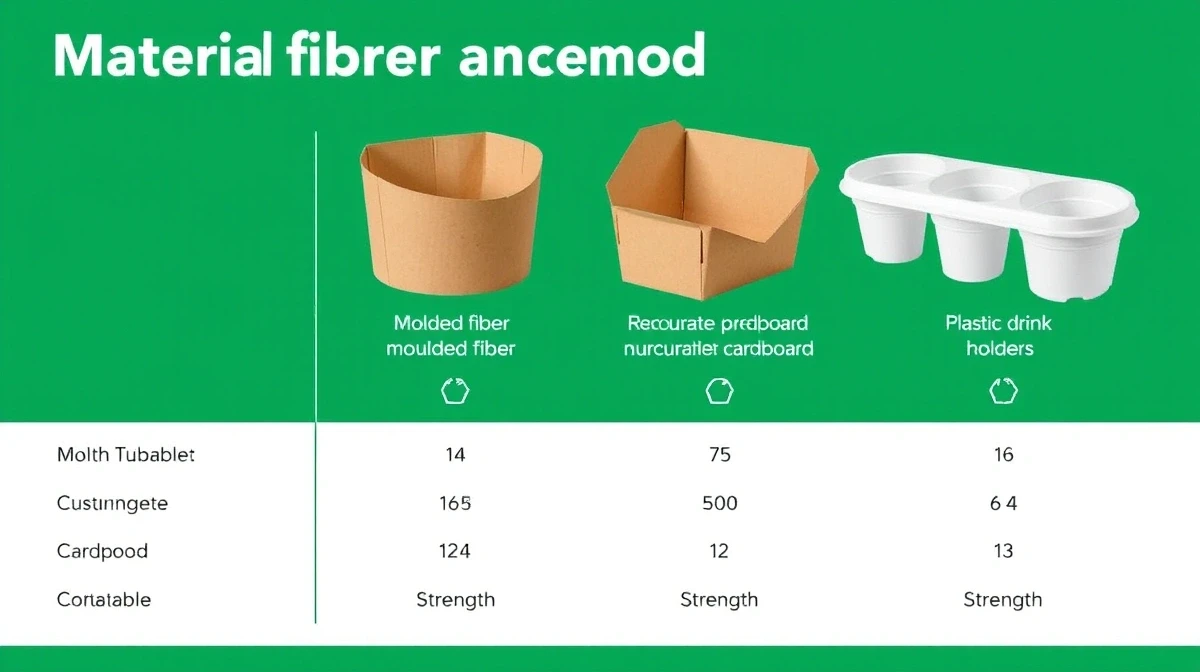

Material Categories:

•Molded Fiber (recycled paper pulp): Eco-friendly, biodegradable, moderate strength

•Corrugated Cardboard: Lightweight, printable, cost-effective

•Plastic (PP, PET): Reusable, high strength, not biodegradable

•Hybrid (Cardboard + Plastic Insert): Combines branding space with durability

🎯 Industry Insight: Starbucks’ shift from 4-cup plastic trays to molded fiber carriers in 2020 reduced plastic waste by 1.2 million pounds annually while maintaining 99.2% carry success rate (no spills during handoff to vehicle).

coffee cups, showing er” class=”wp-image-flux” style=”border-radius: 12px; box-shadow: 0 4px 12px rgba(0,0,0,0.1);”/>

coffee cups, showing er” class=”wp-image-flux” style=”border-radius: 12px; box-shadow: 0 4px 12px rgba(0,0,0,0.1);”/>

The Physics of Carrying Beverages:

When carrying multiple drinks, stability depends on keeping the load’s center of gravity directly above the hand grip. Asymmetric designs cause rotational torque, leading to tipping.

Load Distribution Analysis:

Recommendation: For 4+ cup carriers, square or circular grids with centered handles provide best stability. Linear arrangements should only be used for 2-cup carriers.

Grip Force Requirements:

Handle Shape Optimization:

Anti-Slip Features:

•Textured grip surfaces: Reduces slipping by 35% vs. smooth cardboard

•Rubberized coating (on reusable plastic carriers): 62% slip reduction

•Die-cut finger grooves: Improves grip security without adding cost

Standard Dimensions:

•Footprint: 180-220mm × 90-110mm

•Cup Slot Diameter: 75-95mm (adjustable for 8-20 oz cups)

•Height: 100-140mm (supports cup with lid)

Design Options:

Best Applications:

•Drive-thru coffee shops: Quick handoff, minimal carry distance

•Takeaway counters: Couples ordering 2 drinks

•Home delivery: Small orders requiring compact packaging

Standard Dimensions:

•Footprint: 200-240mm × 200-240mm (square) or 220mm × 120mm (linear)

•Cup Slot Diameter: 75-95mm (standard), 85-105mm (large)

•Height: 110-150mm

Configuration Comparison:

Premium Features for 4-Cup Carriers:

•Cup dividers: Prevent cups from touching and destabilizing each other

•Moisture barriers: Wax or PLA coating to prevent condensation weakening

•Stackable design: Carriers nest when empty for storage efficiency

•Dual handles: Side handles for two-hand carry on longer distances

Best Applications:

•Office coffee runs: 4 drinks is the most common group order size

•Family takeaway: Parents with children (1 drink per person)

•Catering prep: Modular stacking for event transport

Standard Dimensions:

•Footprint: 280-320mm × 200-240mm (2×3 grid) or 260-300mm diameter (circular)

•Cup Slot Diameter: 75-95mm

•Height: 120-160mm

•Weight Capacity: 6-8 lbs (loaded with 16 oz drinks)

Handle Configurations:

Structural Reinforcements:

•Double-wall construction: Prevents sagging under 6-8 lb load

•Bottom support panel: Distributes weight across entire base

•Corner bracing: Prevents torsional deformation when carried unevenly

Best Applications:

•Catering events: Wedding receptions, corporate meetings

•Large group orders: Sports teams, construction sites

•Delivery services: Multi-stop routes with consolidated orders

Properties:

•Material: 100% recycled paper pulp, molded under heat/pressure

•Strength: Moderate (holds 4-6 lbs before deformation)

•Moisture Resistance: Low (requires coating or accepts 10-15% strength loss)

•Compostability: ✅ Home compostable (4-8 weeks)

•Recyclability: ✅ Curbside accepted

•Cost: Medium ($0.15-0.28 per 4-cup carrier)

Advantages:

•Strong sustainability message (100% recycled, compostable)

•Rigid structure (doesn’t collapse when wet like cardboard)

•Unique texture provides natural grip

Limitations:

•Limited printability (absorbs ink unevenly)

•Heavier than cardboard (15-25% more weight)

•Longer production lead times (molding process)

Best For: Eco-conscious brands, café chains with sustainability commitments, markets with composting infrastructure.

Properties:

•Material: Virgin or recycled kraft liner + fluted medium

•Strength: Moderate-High (single-wall holds 4-6 lbs, double-wall holds 8-12 lbs)

•Moisture Resistance: Low-Medium (improved with wax or PLA coating)

•Compostability: ✅ If uncoated; ❌ if wax/PLA coated

•Recyclability: ✅ Widely accepted (if uncoated)

•Cost: Low ($0.08-0.18 per 4-cup carrier)

Advantages:

•Excellent printability (CMYK, flexo, offset)

•Lightweight (reduces shipping costs)

•Ships flat (efficient storage/transport)

•Fast production turnaround

Limitations:

•Weakens significantly when wet (60-70% strength loss)

•Prone to tearing at handle cutouts under heavy loads

•Less distinctive texture than molded fiber

Best For: High-volume operations prioritizing cost, businesses requiring full-color branding, drive-thru environments (short carry distance).

Properties:

•Material: Polypropylene (PP) or recycled PET

•Strength: Very High (holds 12+ lbs without deformation)

•Moisture Resistance: Excellent (no structural impact)

•Compostability: ❌ Not biodegradable

•Recyclability: ✅ Accepted in most programs (PP #5, PET #1)

•Cost: High initial ($1.50-3.50 per carrier), low per-use

Advantages:

•Durable for 50-100+ uses

•Easy to clean and sanitize

•No moisture-related weakening

•Excellent for long-distance carrying

Limitations:

•High upfront cost (requires deposit/return system)

•Negative sustainability perception vs. paper

•Requires washing infrastructure

Best For: Catering companies, corporate cafeterias with return systems, delivery services with reusable container programs.

Tapered vs. Cylindrical Slots:

Recommendation: For multi-size cup operations (e.g., S/M/L/XL coffee), use tapered slots with 75mm base and 95mm top opening to accommodate 8-24 oz cups.

Anti-Rotation Features:

•Cross-dividers: Prevent cups from rotating within slots

•Grippy base texture: Friction pads reduce sliding (molded fiber natural advantage)

•Snap-fit tabs: Lock cup rims in place (premium carriers only)

Storage Optimization:

Recommendation: For businesses ordering >1,000 carriers/month, prioritize flat-packed foldable designs. For <500/month, pre-assembled nested carriers save labor time.

Failure Modes and Solutions:

Heavy-Duty Options for 6-Cup Carriers:

•T-handle with horizontal brace: Distributes load across wider area

•Dual-material handle: Cardboard body + plastic handle insert

•Origami-fold reinforcement: Strategic folding creates load-bearing ridges

Available Branding Surfaces:

Design Best Practices:

1. Prioritize Top Panel:

•Large logo: 60-100mm diameter, centered

•Tagline: Along top edge, readable from above

•Color contrast: High-contrast brand colors (works in peripheral vision)

2. Optimize Side Panels for Recognition:

•Repeating logo pattern: Ensures visibility from any angle

•Bold typography: Readable at 2-3 meters (car window visibility)

•Brand colors: Consistent application creates “brand block” in crowds

3. Use Bottom for QR Codes/Promotions:

•Scan before loading: Customers see bottom when carrier is handed over

•Promotional codes: “Scan for 10% off next order”

•Social media prompts: “Share your coffee run #YourBrandName”

Campaign Examples:

ROI on Limited Editions:

•Social media engagement: 3.2x higher post shares vs. standard packaging

•Collectibility factor: 18% of customers keep branded carriers (vs. 4% for generic)

•Press coverage: Unique designs generate local media attention (free PR)

Load Testing Standards:

•ASTM D4169: Package performance testing (simulates distribution hazards)

•ISTA 3A: General simulation test for parcel delivery

•Custom Drop Test: Loaded carrier dropped from 30cm height (should not spill)

Recommendation: Design for 1.5-2.0× safety factor to account for:

•User error (overfilling cups)

•Environmental factors (condensation weakening)

•Sudden movements (door closing, stepping off curb)

Universal Fit vs. Custom Sizing:

Standard Cup Diameter Ranges:

## Sourcing and Cost Analysis

*Assumes 100 uses before replacement

Inventory Management Tips:

•High-Volume Stores (>500 carriers/week): Order 8-12 weeks supply with full customization

•Medium-Volume (100-500/week): Order 6-8 weeks supply with 1-color print

•Low-Volume (<100/week): Stock generic + apply branded stickers as needed

❌ Mistake #1: Choosing 4-cup linear carrier instead of square grid to save footprint space

✅ Correct Approach: Square grids provide 40% better stability due to centered center of gravity—worth the slightly larger footprint

❌ Mistake #2: Under-specifying handle reinforcement to save $0.02 per carrier

✅ Correct Approach: Handle failures create bad customer experiences worth far more than 2-cent savings; invest in reinforced grips

❌ Mistake #3: Ordering universal-fit carriers without testing actual cup sizes

✅ Correct Approach: Request samples and test with your smallest and largest cups to verify secure fit before bulk orders

❌ Mistake #4: Ignoring moisture resistance for iced beverage operations

✅ Correct Approach: Specify PLA or wax coating for carriers serving cold drinks with condensation (prevents 30-40% of structural failures)

Multiple drink holders (cup carriers) are portable containers designed to securely transport 2-6 beverages simultaneously. They feature individual cup slots, reinforced handles positioned for balanced weight distribution, and collapsible construction for efficient storage.

Square 2×2 grid configurations provide optimal stability by centering the load’s center of gravity directly above the handle. This reduces tip risk by 65% compared to linear 1×4 arrangements and allows comfortable one-hand carrying up to 50 meters.

Standard 4-cup cardboard carriers hold 4-6 lbs (rated capacity with 1.5× safety factor). Double-wall 6-cup carriers support 8-12 lbs. Reusable plastic carriers handle 15+ lbs. Always verify load capacity matches your largest cup size when filled.

Molded fiber offers superior rigidity when wet (retains 85-90% strength vs. cardboard’s 30-40%) and provides stronger sustainability messaging (100% recycled, home compostable). Cardboard excels in printability and costs 30-50% less. Choose based on brand priorities.

MOQs vary: 3,000-5,000 pieces for single-color printing, 5,000-10,000 for full-color CMYK. Some suppliers offer 1,000-2,000 piece minimums using stock carriers with custom sticker application (15-25% higher per-unit cost).

Reinforce handles with double-ply cardboard patches at cutout edges (+5-8% cost), use rounded corners instead of sharp angles to reduce stress concentration, and ensure die-cutting creates smooth edges without micro-tears.

Flat-packed carriers save 95%+ storage space and reduce shipping costs by 60-70%, but require 3-5 seconds assembly time per carrier. Pre-assembled nested carriers save labor but need 10-15× more warehouse space. Choose flat-pack for >1,000 carriers/month.

Ergonomically designed multiple drink holders solve a fundamental challenge in beverage service: enabling customers to safely carry group orders without spills or discomfort. By applying biomechanical principles—centered load distribution, optimized handle shapes, and structural reinforcements—well-designed carriers reduce spillage from 15-20% to under 3% while improving customer satisfaction.

Key Takeaways:

1.Square 2×2 grids provide best stability for 4-cup carriers by centering load over handle

2.Handle reinforcement is worth the 5-8% cost premium to prevent tear-out failures

3.Molded fiber excels in moisture resistance (85-90% strength retention when wet vs. cardboard’s 30-40%)

4.Tapered cup slots adapt to 8-24 oz range, eliminating need for multiple SKUs

5.Flat-packed carriers save 95% storage space and reduce shipping costs by 60-70%

Whether you operate a drive-thru coffee chain, catering service, or fast-casual restaurant, investing in properly engineered drink carriers pays back through reduced product waste, higher customer satisfaction scores, and enhanced brand visibility during the 5-20 minute carry window.

Papacko manufactures ergonomic multiple drink holders from 2-cup to 6-cup configurations in both molded fiber and corrugated cardboard. Our carriers feature reinforced handles, moisture-resistant coatings, and full-color customization options starting at 5,000 pieces.

Get in touch:

Last Updated: November 2025