Last Updated: November 2025

Reading Time: 8-10 minutes

Author: Papacko Content Team

Paper bowls have become the sustainable standard for serving soups, salads, grain bowls, and hot entrées. But a bowl without a proper lid creates spillage risks, temperature loss, and transportation challenges. Not all paper lids fit equally well—a loose lid allows leaks during delivery, while an overly tight lid tears when customers try to remove it. Understanding lid-to-bowl compatibility, seal mechanisms, and structural design separates packaging that enhances the customer experience from solutions that generate complaints and waste.

This guide examines paper bowl lid technologies, compares fit precision across manufacturing standards, and provides selection frameworks for different food types and service models.

In this article, you’ll learn:

•Lid-to-bowl fit specifications and tolerance requirements for secure sealing

•Seal mechanism types (snap-on, friction-fit, rolled-edge) and their leak prevention effectiveness

•Stackability engineering for efficient storage and transport

•Material compatibility between different bowl and lid constructions

💡 Quick Takeaway: Paper bowl lids using snap-fit rim designs with ±0.5mm diameter tolerance achieve 95-98% leak-free performance vs.

75-85% for basic friction-fit lids.

Vented lid designs reduce condensation buildup by 60-70% for hot foods, preventing soggy textures that plague 40% of deliveries using non-vented lids.

Paper lids for bowls are disposable or compostable covers designed to secure contents during storage, transport, and consumption. They feature:

•Material: Paperboard (single or multi-layer, 250-450 GSM), molded fiber, or paper-plastic hybrid

•Coating: PLA, PE, or water-based barriers for moisture/grease resistance

•Fit Mechanism: Snap-on rim, friction edge, tuck flange, or rolled edge

•Functional Features: Venting holes, tab handles, window cutouts

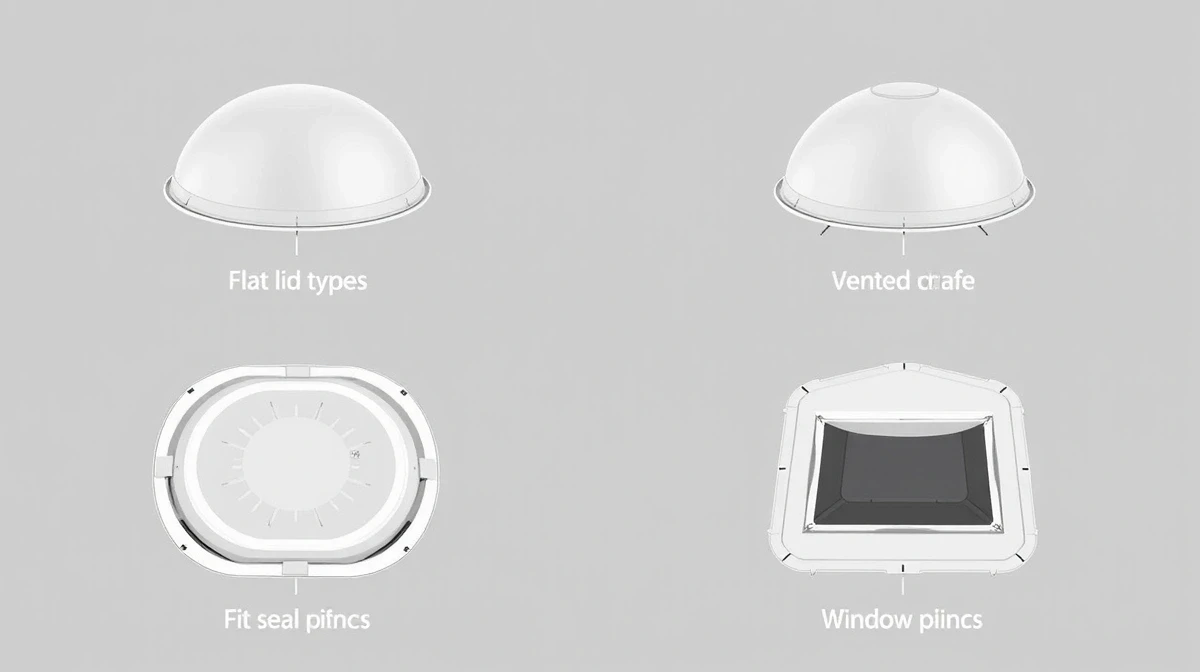

Primary Lid Categories:

> 🎯 Industry Insight: Sweetgreen transitioned from plastic dome lids to molded fiber paper lids in 2023 across 200 locations, reducing plastic usage by 23 tons annually while maintaining <2% lid-related complaints through optimized 380 GSM construction and precision rim tolerances.

Critical Fit Dimensions:

Bowl Size Standards and Compatible Lids:

Manufacturer Compatibility Matrix:

Different paper bowl manufacturers use slightly different rim specifications:

Recommendation: Always test lid-bowl compatibility before bulk orders, even when sizes nominally match. Order 50-100 sample sets and conduct real-world tests with your menu items.

Mechanism: Lid features raised bead or lip that clicks over bowl’s rolled or stepped rim.

Performance Characteristics:

Best Applications:

•Delivery/transport: Vibration and movement don’t dislodge lid

•Hot liquids: Pressure from steam reinforces seal

•High-volume operations: Consistent performance reduces failures

Failure Modes:

•Incomplete seating: If staff don’t press fully around rim (15-20% of issues)

•Rim deformation: Over-tightening can crack bowl rim (5% of failures)

Mechanism: Lid rests on bowl rim with tight interference fit (no click/snap).

Performance Characteristics:

Best Applications:

•Dine-in: Short holding times, minimal movement

•Cold foods: No pressure from steam

•Low-budget operations: Cheaper than snap-on (20-30% less)

Failure Modes:

•Side impact: Bumping during transport pops lid (40% of issues)

•Stacking pressure: Weight of stacked bowls pushes lids down into food

Mechanism: Lid edge tucks under outward flange on bowl rim.

Performance:

•Seal: Good (85-90%) but requires precise manufacturing

•Security: Very high (almost impossible to accidentally dislodge)

•Removal: Can be difficult for elderly/children (requires lifting flange)

Best For: Institutional feeding (hospitals, schools) where security > ease of opening.

Problem: Hot food generates steam inside sealed container → condensation forms on lid → drips onto food → soggy texture.

Venting Solution: Small holes (1-3mm diameter) allow steam escape while maintaining most of seal integrity.

Condensation Reduction Data:

Trade-offs:

•Leak Risk: Vents can allow liquid spills if bowl tips >30° (delivery concern)

•Heat Loss: Vented lids lose 15-20% more heat than solid lids over 30 minutes

Design Optimization:

•Vent Placement: Offset from center (prevents direct contact with food surface)

•Vent Size: 1.5-2mm optimal (balance steam escape vs. spill risk)

•Vent Count: 4-6 holes for 32oz bowl (2-3 for 16oz)

Recommendation: Use vented lids for hot soups, stews, and steamed foods served for immediate consumption or <20 minute delivery. Use solid lids for longer transport (heat retention priority).

Single-Layer Construction:

•GSM Range: 250-320

•Rigidity: Moderate (can flex/cave under stacking)

•Cost: $0.04-0.08 per lid

•Best For: Light items, low-stack heights (<5 bowls)

Multi-Layer (Laminated) Construction:

•Layers: 2-3 layers of paperboard (total 350-450 GSM)

•Rigidity: High (resists crushing)

•Cost: $0.08-0.15 per lid

•Best For: Heavy toppings, high-stack catering, transport

Structural Comparison:

### Molded Fiber vs. Paperboard

Molded Fiber (Bagasse/Pulp) Lids:

•Texture: Rough, natural (not smooth)

•Strength: High (3D molded structure)

•Moisture Resistance: Requires coating (absorbs moisture otherwise)

•Sustainability: 100% compostable (if uncoated or water-coated)

•Cost: +20-40% vs. paperboard

Paperboard (Flat or Formed) Lids:

•Texture: Smooth, printable

•Strength: Moderate (relies on thickness)

•Moisture Resistance: Depends on coating

•Sustainability: Recyclable (water-based coating) or compostable (PLA coating)

•Cost: Baseline

Application Guide:

## Stackability and Storage Efficiency

Lid Nesting Configurations:

Trade-off: Aggressive nesting improves storage but can make lids harder to separate during service (lids stick together).

De-Nesting Solutions:

•Textured surfaces: Micro-embossing prevents vacuum seal between lids

•Rim bumps: Small raised dots create air gaps

•Anti-static coating: Reduces static cling (especially in dry environments)

Problem: Bowls with lids attached don’t stack efficiently (lids add height, prevent nesting).

Solutions:

Optimal Strategy: Store bowls and lids separately in warehouse. Assemble lid-on-bowl only after filling (just before service/delivery).

Budget Tier:

•Material: 250-280 GSM single-layer paperboard

•Fit: Friction-fit (loose tolerance ±1-1.5mm)

•Cost: $0.04-0.06 per lid

•Failure Rate: 15-25% (leaks, pop-offs during transport)

•Best For: Dine-in only, dry foods

Standard Tier:

•Material: 300-320 GSM paperboard or light molded fiber

•Fit: Snap-on rim (±0.5mm tolerance)

•Cost: $0.07-0.10 per lid

•Failure Rate: 2-5%

•Best For: Delivery, most applications

Premium Tier:

•Material: 380-450 GSM multi-layer or heavy molded fiber

•Fit: Precision snap-on (±0.3mm tolerance)

•Cost: $0.12-0.18 per lid

•Failure Rate: <1%

•Best For: High-value meals, long delivery, catering

Total Cost Including Failures:

Key Finding: Standard-tier lids offer lowest total cost despite 75-150% higher unit price vs. budget options.

Coating Comparison for Lids:

Performance by Food Type:

Sustainability vs. Performance:

•Recyclable (water-based): Degrades faster → suitable for <30 min service

•Compostable (PLA): Requires industrial facility (30% consumer access)

•High-performance (PE): Neither recyclable nor compostable → use only when necessary

Print Quality by Material:

Print Zones:

•Lid Center: High visibility (always visible)

•Lid Rim: Visible when stacked

•Interior (Underside): Rarely seen (waste of ink)

Cost Add-Ons:

•1-Color Print: +$0.02-0.04 per lid (MOQ 3,000-5,000)

•2-Color Print: +$0.04-0.07 (MOQ 5,000-10,000)

•Full CMYK: +$0.08-0.15 (MOQ 10,000-20,000)

❌ Mistake #1: Assuming all “medium” lids fit all 32oz bowls

✅ Correct Approach: Measure bowl rim diameter with calipers, verify lid fits within ±0.5mm tolerance before bulk orders

❌ Mistake #2: Using non-vented lids for hot soups to prevent leaks

✅ Correct Approach: Vented lids reduce condensation (preventing soggy food) while maintaining 90%+ seal if properly designed (1.5-2mm holes, offset placement)

❌ Mistake #3: Choosing budget lids to save $0.03 per unit

✅ Correct Approach: Budget lids have 15-25% failure rate costing $0.60-1.20 per order in replacements/service time—upgrade to standard lids

❌ Mistake #4: Ordering molded fiber lids for graphic-heavy branding

✅ Correct Approach: Molded fiber has rough surface with poor print quality—use smooth paperboard for detailed logos/graphics

Paper lids for bowls are disposable covers made from paperboard (250-450 GSM) or molded fiber with moisture/grease barriers. They feature snap-on rims, friction fits, or tuck flanges to secure contents during storage, transport, and consumption in eco-friendly food service applications.

Measure your bowl’s top rim diameter with calipers. Match to lid within ±0.5mm tolerance for snap-fit designs or ±1mm for friction-fit. Standard sizes: 110-115mm (12-16oz bowls), 135-145mm (24-32oz), 165-180mm (32-48oz). Always test compatibility before bulk orders.

Snap-on lids click into place via raised bead engaging bowl rim (95-98% leak-free, harder to apply/remove). Friction-fit lids rest on rim with interference (75-85% leak-free, easy on/off). Snap-on costs 15-25% more but reduces delivery failures by 50-60%.

Yes for immediate consumption or <20 min delivery. Vented lids (4-6 holes, 1.5-2mm diameter) reduce condensation by 60-70%, preventing soggy food textures. Use solid lids for longer transport (>30 min) to retain heat. Vents add minimal cost (+$0.01-0.02).

Depends on coating. Water-based coated paperboard lids are widely recyclable. PLA-coated lids contaminate recycling but are industrially compostable. PE-coated lids are neither recyclable nor compostable. Uncoated molded fiber is home compostable and recyclable.

Budget (250-280 GSM, friction-fit): $0.04-0.06, Standard (300-320 GSM, snap-on): $0.07-0.10, Premium (380-450 GSM, multi-layer): $0.12-0.18 per lid (MOQ 1,000+). Custom printing adds $0.02-0.15 depending on complexity.

Yes but inefficiently. Bowls with attached lids stack 250-300mm height per 10 units (no nesting). Bowls alone nest to 80-100mm. Best practice: store bowls and lids separately, assemble after filling. Stepped-rim systems allow partial nesting with lids (120-150mm per 10 units).

Paper bowl lids represent a critical junction between sustainability commitments and operational reliability. The difference between successful eco-friendly packaging and frequent service failures lies not in choosing “paper lids” generically but in understanding how fit precision, seal mechanisms, venting systems, and material specifications interact to create consistent performance across diverse food applications.

Key Takeaways:

1.±0.5mm rim diameter tolerance is critical for snap-fit lids to achieve 95-98% leak-free performance

2.Snap-on mechanisms outperform friction-fit (2-5% failure vs. 15-25%) and justify 15-25% cost premium for delivery operations

3.Vented lids reduce condensation by 60-70% for hot foods, preventing soggy textures that affect 40% of non-vented deliveries

4.Standard-tier lids (300-320 GSM, snap-on) offer lowest total cost when accounting for failures and replacements

5.Material choice determines end-of-life: Water-based coating = recyclable, PLA = compostable (industrial), uncoated molded fiber = home compostable

Whether you operate a fast-casual restaurant, meal prep service, or catering company, investing time in lid specification—measuring bowl dimensions precisely, testing compatibility with actual menu items, selecting appropriate venting for food types, and choosing sustainable materials aligned with local waste infrastructure—separates packaging as a cost center from packaging as an operational advantage.

•Sustainable Packaging Solutions

Papacko manufactures paper bowl lids from 250-450 GSM paperboard and molded fiber with customizable coatings (PE, PLA, water-based), fit mechanisms (snap-on, friction-fit, tuck-flange), and venting configurations. Our precision manufacturing ensures ±0.5mm tolerance for reliable sealing starting at 1,000-piece MOQs.

Get in touch:

Last Updated: November 2025

Focus Keyword: paper lids for bowls

URL Slug: paper-lids-for-bowls

Meta Title:

Paper Lids for Eco Bowls — Which Type to Choose? | Reliable Food Packaging | Papacko

Meta Description:

Compare paper bowl lid types: fit precision, seal effectiveness, stackability. Expert selection guide for sustainable food packaging solutions.

💡 Configure these settings in Rank Math panel, then delete this box before publishing.