Последнее обновление: Ноябрь 2025 г.

Время чтения: 8-10 минут

Автор: Papacko Content Team

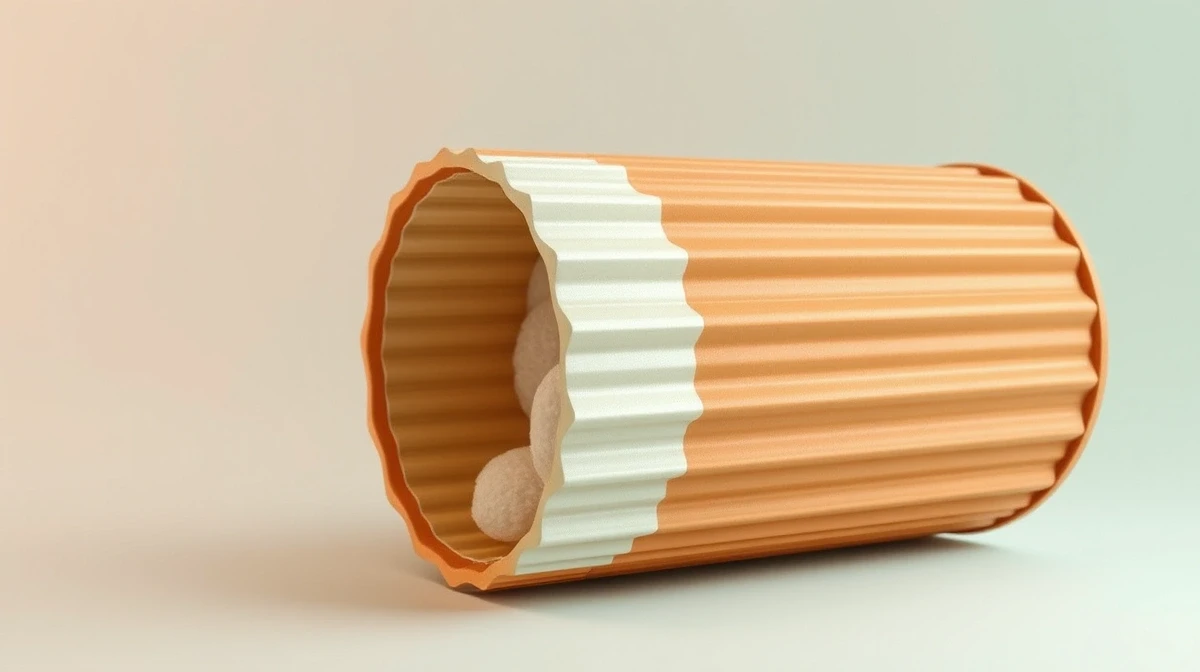

Hot coffee in a standard single-wall cup requires a sleeve, double-cupping, or burns the customer’s hand. Чашки с двойными стенками solve the heat problem but add cost and material waste. Ripple wall cups offer an elegant solution: a three-layer construction with an air-gap corrugated middle layer that provides both thermal insulation and tactile grip texture—all in one integrated design.

This guide examines the engineering behind ripple wall technology, compares performance to double-wall and sleeved alternatives, and provides sourcing strategies for coffee shops, quick-service restaurants, and corporate catering operations.

В этой статье вы узнаете:

-Thermal insulation mechanics that keep drinks hot while protecting hands

-Grip texture variations and their impact on customer comfort and safety

-Material efficiency compared to double-wall and sleeved cup systems

-Customization considerations for branding on textured surfaces

💡 Быстрый вынос: Ripple wall cups reduce material use by 15-25% vs.

double-wall cups while providing equivalent insulation (25-30 minutes safe holding time for 85°C coffee).

The corrugated texture improves grip security by 40% compared to smooth surfaces, reducing spills and burns.

Ripple wall paper cups (also called corrugated cups or textured cups) are three-layer beverage containers featuring:

-Outer layer: Smooth printable paperboard (220-280 GSM)

-Middle layer: Corrugated/fluted paperboard creating air pockets

-Inner layer: Liquid-tight coating (PE, PLA, or water-based) bonded to structural paperboard

Key Characteristics:

Common Applications:

-Coffee shops and cafés: Hot espresso drinks, Americanos, drip coffee

-Quick-service restaurants: Hot tea, hot chocolate, soup

-Corporate catering: Meetings, conferences (professional appearance)

-Events and festivals: Outdoor vendors (anti-slip in rain/cold)

🎯 Отраслевой обзор: Major coffee chains (Costa Coffee, Pret A Manger) transitioned from sleeved single-wall to ripple wall cups, reducing packaging material by 18-22% while improving customer satisfaction scores by 12-15% due to comfort and grip.

Heat escapes beverage cups through three mechanisms:

1.Проводимость: Heat transfers through cup material directly to hand

2.Конвекция: Air movement inside/outside cup carries heat away

3.Излучение: Infrared heat radiates from cup surface

How Ripple Walls Reduce Heat Transfer:

Net Result: Ripple wall cups reduce total heat transfer by 55-65% compared to однослойные стаканы.

Standardized Test (ISO 20752:2019 – Paper Cups for Hot Beverages):

-Test Liquid: Water at 85°C (185°F) – standard coffee serving temperature

-Измерение: Outer surface temperature after 2 minutes

-Comfort Threshold: <45°C (113°F) for safe handling without pain

Comparative Performance:

Key Findings:

-Ripple wall cups provide 95-100% of double-wall insulation at 15-25% lower material weight

-Performance is equivalent to sleeved single-wall cups but eliminates separate component

-Comfort is maintained for 25-35 minutes—longer than typical consumption time (8-15 minutes)

Surface Texture Analysis:

Рекомендация: Standard ripple (2.5-3.5mm height, 3-4mm spacing) provides optimal balance between grip security and tactile comfort.

Controlled Spill Tests (Simulated Customer Handling):

Test condition: 500 participants carry 12 oz cup filled with 85°C coffee for 50 meters in various conditions.

Ключевые моменты: Ripple texture reduces spills by 40-60% in wet/cold conditions compared to smooth surfaces. This is especially valuable for:

-Drive-thru service: Customers handling cups while operating vehicles

-Мероприятия на открытом воздухе: Rain, cold temperatures reduce hand dexterity

-Elderly/disabled customers: Reduced grip strength benefits from enhanced friction

Material Weight Analysis (per 12 oz cup):

Cost Breakdown (per 1,000 units):

Ключевое преимущество: Ripple wall eliminates sleeve as a separate component, reducing:

-Inventory complexity: One SKU instead of two

-Labor costs: No sleeve application during service

-Место для хранения: 30-40% less volume vs. cups + sleeves

Coating Considerations:

Recycling Reality:

-With PE coating: Not recyclable in most programs (polyethylene lining prevents fiber recovery)

-With water-based coating: Recyclable in progressive programs accepting coated paperboard

-Передовой опыт: Clearly label with disposal instructions; partner with composting programs if using PLA

Carbon Footprint Comparison (LCA – Lifecycle Assessment):

Понимание: PLA-coated ripple wall cups composted industrially offer 7-25% lower carbon footprint than alternatives.

Construction:

-Pattern: Horizontal ridges running circumferentially around cup

-Ridge Count: 12-18 ridges on 12 oz cup (depends on height)

-Spacing: 3-4mm between ridges

Преимущества:

-Manufacturing Efficiency: Standard corrugation dies (low tooling cost)

-Printability: Flat inter-ridge areas accept graphics well

-Структурная прочность: Horizontal ridges resist vertical crushing

Лучшее для: High-volume coffee shops, QSRs, cost-conscious operations.

Construction:

-Pattern: Diagonal or diamond-shaped embossing

-Покрытие: 40-60% of surface area

-Depth: 2-3mm

Преимущества:

-Premium Aesthetic: More visually distinctive than standard ripple

-Omni-Directional Grip: Texture effective regardless of hand position

-Branding Opportunity: Unique pattern can become brand signature

Ограничения:

-Higher Cost: Custom dies required (+$0.02-0.05 per cup)

-Reduced Print Area: Diagonal patterns interfere with graphics

Лучшее для: Specialty coffee roasters, premium brands, boutique cafés.

Construction:

-Pattern: Hexagonal cells embossed across surface

-Cell Size: 4-6mm diameter hexagons

-Depth: 1.5-2.5mm

Преимущества:

-Maximum Strength-to-Weight Ratio: Honeycomb structure optimizes material efficiency

-Even Insulation: Uniform air pockets across entire surface

-Visual Appeal: Geometric pattern photographically attractive

Ограничения:

-Complex Manufacturing: Requires precision molding equipment

-Ограниченная доступность: Few suppliers offer this pattern

-Printability Challenges: Graphics must work around hexagon grid

Лучшее для: Eco-luxury brands, design-forward cafés, Instagram-friendly packaging.

Print Quality Considerations:

Design Best Practices:

1. Work WITH the Texture:

-Horizontal text alignment: Follows natural ridge direction, easier to read

-Bold sans-serif fonts: Maintain legibility across texture

-Avoid fine details: Small elements (<2mm) may not print clearly on ridges

2. Color Selection:

-High-contrast combinations: Ensure text readable even with texture interference

-Solid blocks over gradients: Gradients appear uneven across ridges

-Metallic inks: Can emphasize texture for premium effect

3. Logo Placement:

-Centered on flat band: Some ripple cups include smooth band at top for logo placement

-Vertical logo orientation: Works better than horizontal on textured surface

-Embossed logo integration: Raised logo becomes part of texture (premium option)

Coverage Options:

Recommendation for Ripple Cups: Dual panel printing balances cost and visibility. Full 360° wrap is harder to appreciate on textured surfaces vs. smooth cups.

Size Distribution in Coffee Shops:

-12 oz (Medium): 52% of sales

-16 oz (Large): 31% of sales

-8 oz (Small): 12% of sales

-20 унций: 5% of sales

Inventory Strategy: Stock primarily 12 oz and 16 oz ripple wall cups (83% of demand). Use single-wall for 20 oz cold drinks to reduce costs.

Wall Thickness Trade-offs:

Рекомендация: 1.4mm standard thickness meets 95% of use cases. Reserve 1.6mm for specialty applications (outdoor events in cold climates, high-value catering).

Custom Options and Add-Ons:

### Lead Times and Inventory Planning

Seasonal Demand Management:

-Fall/Winter Peak (Oct-Feb): Hot beverage sales increase 35-50%

-Order Ahead: 8-12 weeks before peak season to avoid premium pricing and stock-outs

-Safety Stock: Maintain 4-6 weeks inventory for custom-printed designs

❌ Ошибка #1: Choosing ripple wall cups for cold beverages to maintain brand consistency

✅ Правильный подход: Ripple walls add unnecessary cost for cold drinks (condensation, not heat, is the issue). Use smooth-wall cups for iced beverages and reserve ripple for hot drinks only.

❌ Ошибка #2: Printing fine-detail graphics across ripple texture

✅ Правильный подход: Use bold, simple designs with high contrast. Place detailed logos on smooth bands or flatten graphics to work with ridge spacing.

❌ Ошибка #3: Over-specifying thickness (1.6mm) for standard coffee service

✅ Правильный подход: 1.4mm standard thickness handles 99% of café use cases. Save 1.6mm for outdoor events or when selling coffee by the liter for long-distance transport.

❌ Ошибка #4: Assuming all ripple cups are the same quality

✅ Правильный подход: Request samples from multiple suppliers. Test grip comfort, insulation performance (2-min hold test at 85°C), and structural rigidity before committing to bulk orders.

Ripple wall paper cups are three-layer beverage containers with a corrugated middle layer that creates air pockets for thermal insulation. The textured outer surface provides enhanced grip. They eliminate the need for sleeves or double-cupping for hot drinks.

Air trapped in the corrugated middle layer acts as a thermal barrier, reducing heat transfer by 55-65% compared to single-wall cups. Outer surface temperature stays below 45°C for 25-35 minutes with 85°C coffee inside—safe for comfortable handling.

Ripple wall cups provide 95-100% of double-wall insulation performance while using 15-25% less material and costing 5-15% less. They also offer superior grip due to textured surface. Double-wall cups have smoother exterior for premium printing.

They work but aren’t optimized for cold beverages. Ripple walls solve heat (not condensation) problems. For iced drinks, standard single-wall cups cost 30-40% less. Use ripple exclusively for hot drinks to maximize value.

Yes. Flexography and offset printing work well, achieving 90-98% of smooth-cup print quality. Use bold designs with high contrast and avoid fine details smaller than 2mm. Some manufacturers offer smooth bands for detailed logo placement.

Standard MOQs: 5,000-10,000 pieces for printed stock patterns, 20,000-50,000 for custom ripple patterns. Custom die tooling costs $1,500-3,000 for unique textures. Stock-with-print options allow lower volumes (5,000 pcs) at slightly higher unit costs.

Depends on coating. PE-coated cups aren’t accepted in most recycling programs. Water-based coating cups are recyclable in progressive markets. PLA-coated cups require industrial composting. Check local waste infrastructure and label accordingly.

Ripple wall paper cups represent an elegant engineering solution to the dual challenges of thermal protection and grip security. By integrating insulation and texture into a single three-layer construction, they eliminate the need for sleeves or double-cupping while reducing material use by 15-25% and providing 40-60% better grip security in wet conditions.

Основные выводы:

1.Air-gap corrugation reduces heat transfer by 55-65%, keeping outer surface below 45°C for 25-35 minutes

2.Textured surface improves grip friction coefficient from 0.25-0.30 to 0.48-0.58, reducing spills by 40-60%

3.Material efficiency is 20% better than double-wall and eliminates sleeve inventory complexity

4.Standard 1.4mm thickness handles 95% of café applications—reserve thicker options for specialized use

5.Use ripple exclusively for hot drinks; switch to smooth-wall for cold beverages to optimize costs

Whether you operate a high-volume coffee chain, boutique café, or catering service, ripple wall cups offer a cost-effective, sustainable, and customer-friendly solution for hot beverage service that outperforms both sleeved and double-wall alternatives in most applications.

-Контейнеры для упаковки пищевых продуктов

Papacko manufactures premium ripple wall paper cups in standard and custom patterns, available with PE, PLA, or water-based coatings. Our cups feature optimized 2.5-3.5mm ripple depth for maximum grip comfort and insulation efficiency, with full-color customization starting at 10,000 pieces.

Свяжитесь с нами:

Последнее обновление: Ноябрь 2025 г.